Waste materials can be recycled into a wide variety of useful goods. Many materials can be converted into charcoal, which means a palm kernel shell charcoal making machine can be a sound investment. If you’re considering investing in a machine like this, but you’re not certain it’s the best option for your needs, these are a few factors you should keep in mind.

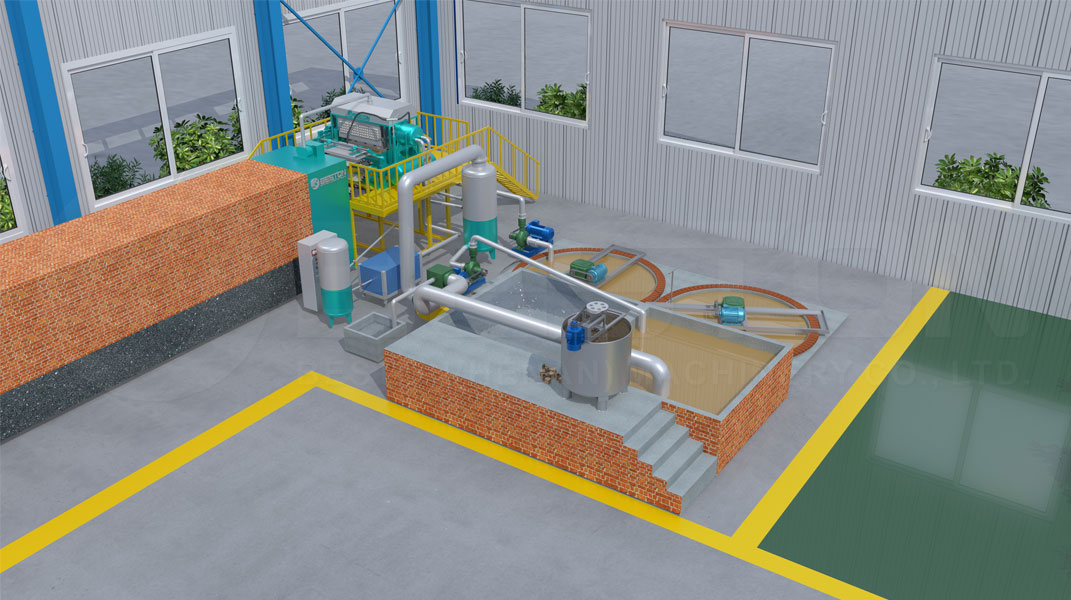

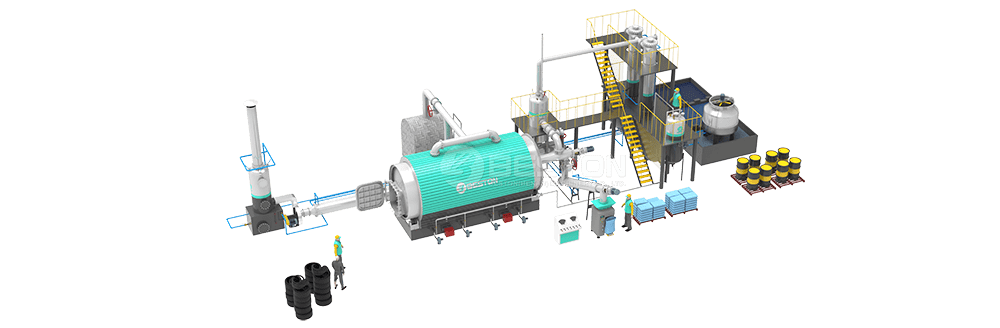

Palm Kernel Shell Charcoal Making Machine

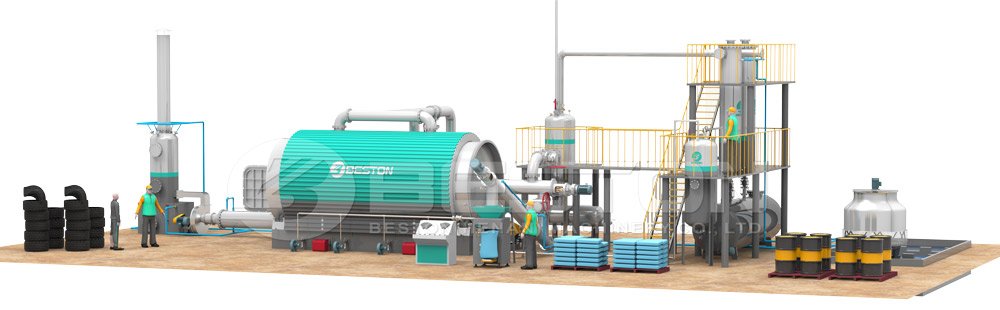

Many Types of Materials Can Be Converted Into Charcoal

Wood, sawdust, and bamboo are just a few of the many materials that can easily be turned into charcoal with the right equipment. You’ll be able to use the materials that you have access to in order to produce charcoal with your equipment.

Being able to recycle many different types of materials means that a palm kernel shell machine offers more flexibility than many similar products on the market. You’ll be able to get a great deal of use out of the equipment that you invest in.

You Don’t Have to Spend a Lot Upfront

The initial cost of your bamboo charcoal machine doesn’t necessarily have to be prohibitively expensive. There are many affordable options to choose from, particularly if you consider vendors in different regions. You may be able to enjoy the benefits of an investment like this without having to invest a significant amount of money.

If you’re looking for a low-cost investment that could pay off for you over time, machinery like this could be an excellent option. Take the time to see what you’re likely to spend on a machine like this and decide if that amount would work for you.

It’s Cost Efficient Equipment

Pricing is likely to be a significant concern when you’re deciding whether you should make an investment. If you’re not sure that you want to invest in a charcoal machine, you should be aware that it’s likely to be a cost effective investment.

As mentioned above, you can purchase this equipment at a very reasonable price point, and most machinery on the market is inexpensive to operate. Your equipment will require very little maintenance, and the charcoal that you produce can be used in a number of ways.

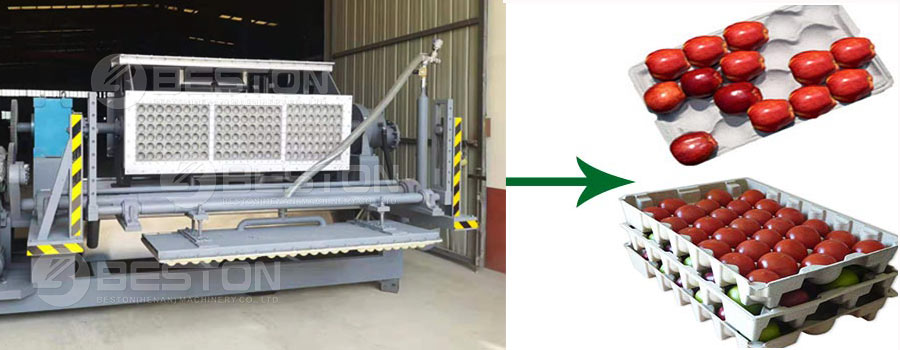

There Are All Kinds of Options

Another significant benefit of purchasing this type of sawdust charcoal machine is that you’ll be able to seek out an option that is in line with your needs. You’ll find machinery in many sizes and at many different price points. You’ll see that many of the models on the market have features that could make them a better fit for you.

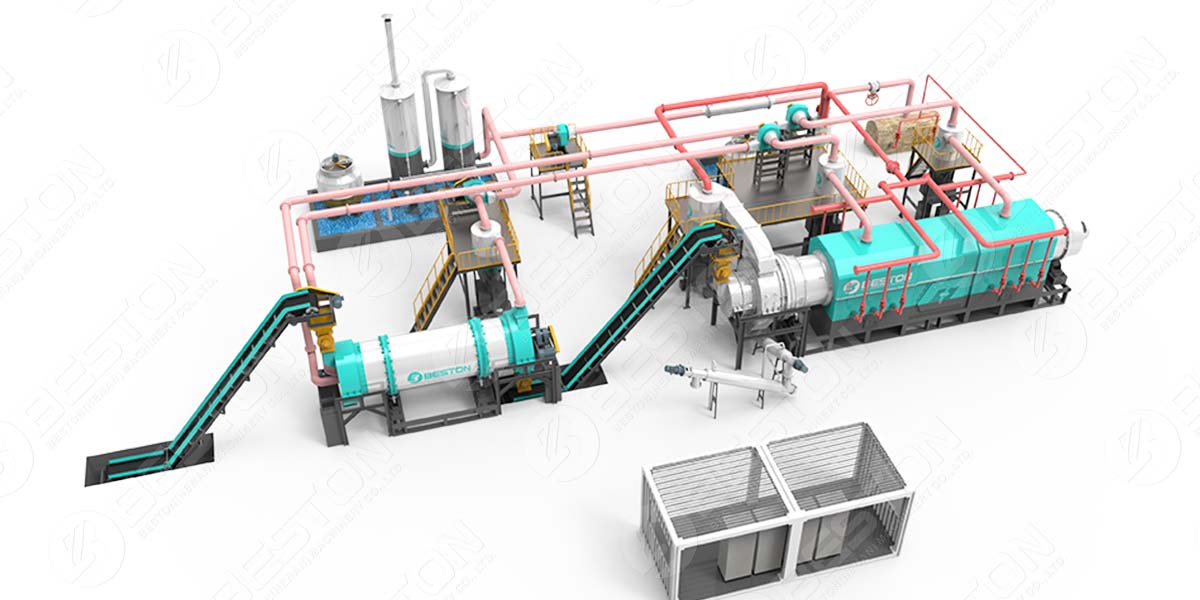

Palm Kernel Shell Charcoal

If you know what you want out of charcoal machinery, you’ll be able to look for equipment that is able of delivering everything that you want. There are many impressive options available, and you should have no trouble finding equipment that can do what you need it to do.

Should you invest in a palm kernel shell charcoal machine? You should look at the benefits that rice husk carbonizer like this can deliver. Once you’ve considered the advantages of an investment like this, you can decide what you’d like to do next.