There are different methods for the treatment of waste tyre. Some common waste tires treatment methods are Retread or recap or remould is a manufacturing process designed to extend the useful lifespan of a worn tyre. The old tread is buffed away, and a new rubber tread is applied to the bare casing using specialized machinery. Retreading is regularly undertaken on airplanes tyres. Retreading is the most environmentally friendly way of recycling used tyres as manufacturing the average car retread takes 4.5 gallons less oil than manufacturing equivalent new tyre. With commercial vehicle tyres, the savings are even greater, estimated to be in the region of 15 gallons per tyre. Land filling is one of the most common ways to tackle the waste tyre problem. Finding reliable pyrolysis plant manufacturers is good for your business.

Methods for the treatment of waste tyre

However, many countries have proposed to ban land filling of the waste tyre, especially the land filling of whole waste tyre. Incineration is a waste treatment technology that involves the combustion of organic materials or substances. Beston tire recycling equipment for sale has newest technology. Incineration of waste materials converts the waste into incinerator bottom ash, flue gases, particulates in which flue gases can be used to generate electric power. Incineration with energy recovery is one of several waste-to-energy technologies although incineration may also be implemented without energy and materials recovery. Incineration reduces the volume of the original waste by 95-96 %. Tyre Derived Fuel (TDF) means waste tyres that are shredded into pieces approximately 1–2 inches in size. The application of TDF is to substitute coal as the energy source due to the fact that waste tyre has a higher heating value than coal.

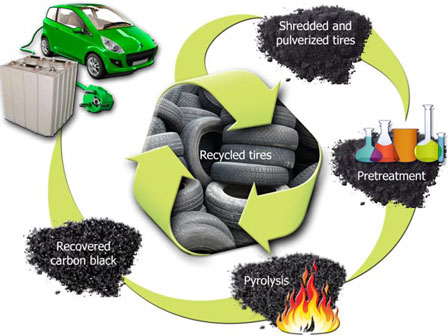

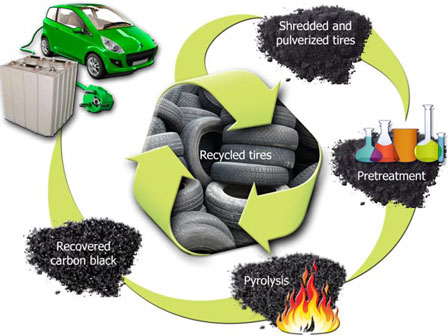

The major use of the TDF is the energy recovery in cement kilns and paper and pulp industries. Co-combustion is the combustion of equal or more than two different types of materials at the same time. Waste tyre co-combustion can be used to improve the combustion of fuels with low energy content. In gasification, combustible material is partially oxidized into a gaseous energy carrier in a high-temperature reducing atmosphere, using air stream or oxygen as the gasification agent. Pyrolysis refers to the thermal decomposition of organic material at elevated temperature in the absence of oxygen. We Beston Machinery are pyrolysis plant manufacturers in China. All models of pyrolysis machine are available for you.

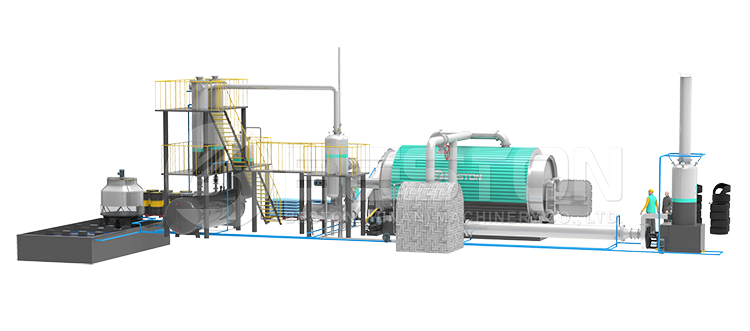

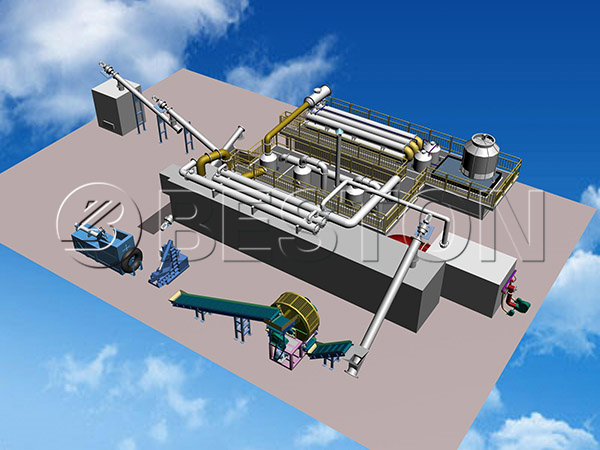

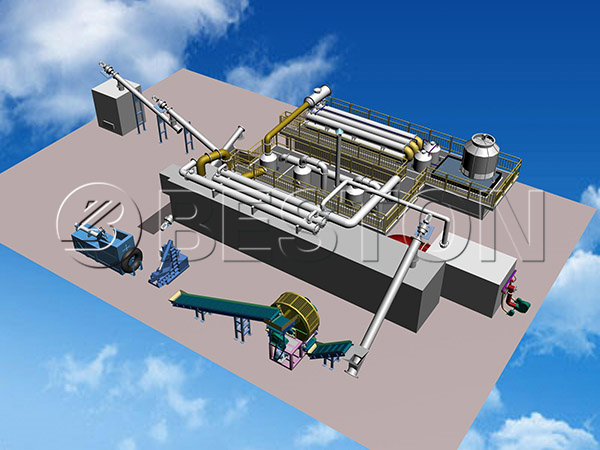

Beston Tyre Pyrolysis Plant in Jordan

Among the waste tires treatment methods, retreading require the waste tyre to be relatively integral, landfilling wasted the possibility of using the tyre for producing high-value added products. Moreover landfilling is banned in many countries due to leaching of metals and contaminants from tire pieces, which if mix with water may cause lever lesion. Thus, retreading and landfilling should not be the universal way to completely solve the waste tyre problem. Many people don’t have a clear understand about pyrolysis system. Recycling waste tyre to raw rubber materials seems practicable; however some other potential waste tires treatment methods found in the world can be even more profitable than conventional recycling of rubber. Materials from tyre, those waste tires treatment methods involves the energy recovery and/or chemicals recovery from the waste tyre. Pyrolysis, incineration, co-combustion, tyre derived fuel (TDF), liquefaction and gasification can recover energy and/or valuable chemicals from the treatment of waste tyres.

However, incineration and tyre derived fuel may involve the emission of hazardous pollutants extremely harmful to human health and the natural environment. The fumes emitted are packed with the many toxic chemicals like volatile organic compounds such as benzene, metals such as lead, polycyclic aromatic hydrocarbons such as benzo(a)pyrene, and synthetic rubber components such as butadiene and styrene. Additionally, the chlorine content in tires leads to the creation of dioxins and furans which are extremely toxic chemicals when tires are burned. Regarding to the emission of waste tyre combustion, the incineration and co-combustion of whole tyre in cement kilns has been banned in a number of countries. And the price of tire recycling equipment is competitive.

Moreover the sulfur composition of waste tyre is normally larger than 1wt%. Thus, incineration and tyre derived fuel should not be suitable for treating the waste tyres. Pyrolysis, gasification and liquefaction (PGL) may be considered to be better ways for the treatment of waste tyres. The tire recycling equipment for sale is currently used for the conversion of carbonaceous materials more extensively in Europe and Japan than in California but may become more important as the supplies of natural fuels become depleted. Further efforts should be conducted to determine the potential value of tires as a resource that can be used to displace petroleum products or natural resources used in energy production. The true market value of tires should be determined based on potential products that can be derived from tire PGL, including electricity, diesel fuel, process heat, pyrolysis oils, and char.

Beston Waste Tires Recycling Pyrolysis Plant

The use of tyre pyrolysis oil as a substitution to diesel fuel is an opportunity in minimizing the utilization of the natural resources. Several research works have been carried out on the pyrolysis of waste automobile tyres. In the tire pyrolysis process, larger hydrocarbon chains break down at certain temperatures in the absence or limited supply of oxygen that gives end product usually containing solid, liquid and gases. If the temperature is maintained at 550 ℃ the main product is liquid which could be a mixture of hydrocarbon depending on the initial composition of waste material. At temperature above 700 ℃, the gas becomes the primary product due to further cracking of the liquids. In the present work pyrolysis oil from used tyres by tire recycling equipment is obtained. Though solid carbon black and pyrolysis gas are also obtained. The liquid obtained is characterized for various physiochemical properties using I S 1448 and compared with that of similar properties of standard diesel sample to find out its suitability as an alternative fuel for internal combustion engine. View https://tyrepyrolysisplants.net/tire-recycling-plant-cost.html.