Considerations for Sawdust Biochar Production

The production of biochar from sawdust through pyrolysis has gained significant attention due to its potential environmental benefits and diverse applications. Sawdust, a byproduct of wood processing, can be converted into biochar, which is valuable in agriculture, soil improvement, and carbon sequestration. However, the process of transforming sawdust into biochar requires careful management of several key factors to ensure the optimal performance and efficiency of the pyrolysis plant. Proper attention to feedstock preparation, reactor design, temperature control, and byproduct management is essential for maximizing yield and ensuring the sustainability of the process.

Feedstock Preparation

The first critical step in the production of biochar from sawdust is the preparation of the feedstock. Sawdust generally has a high moisture content, which can affect the efficiency of the pyrolysis process. It is essential to reduce the moisture content to an optimal level before introducing the material into the sawdust charcoal machine. Drying the sawdust not only improves thermal efficiency but also reduces the energy demand of the pyrolysis process, ultimately enhancing the overall economic viability of the operation.

Additionally, the particle size of the sawdust plays a significant role in the quality and consistency of the biochar. Smaller, uniformly sized particles promote better heat distribution during pyrolysis, leading to more efficient thermal decomposition. Preprocessing the sawdust by shredding or milling it into smaller pieces can improve heat transfer within the reactor and result in higher yields of biochar.

Temperature Control in the Pyrolysis Process

Temperature control is another vital aspect of wood to charcoal machine. The pyrolysis process involves heating the sawdust to temperatures typically ranging from 400°C to 600°C in the absence of oxygen. The temperature directly influences the quality and properties of the produced biochar, including its porosity, carbon content, and surface area.

If the temperature is too low, the pyrolysis process will be incomplete, leading to lower biochar yield and insufficient carbon sequestration. On the other hand, excessively high temperatures may result in excessive vaporization of the organic material, decreasing biochar yield and potentially causing the formation of undesirable byproducts. Thus, maintaining a stable and precise temperature is essential for achieving a high-quality product.

Reactor Design and Efficiency

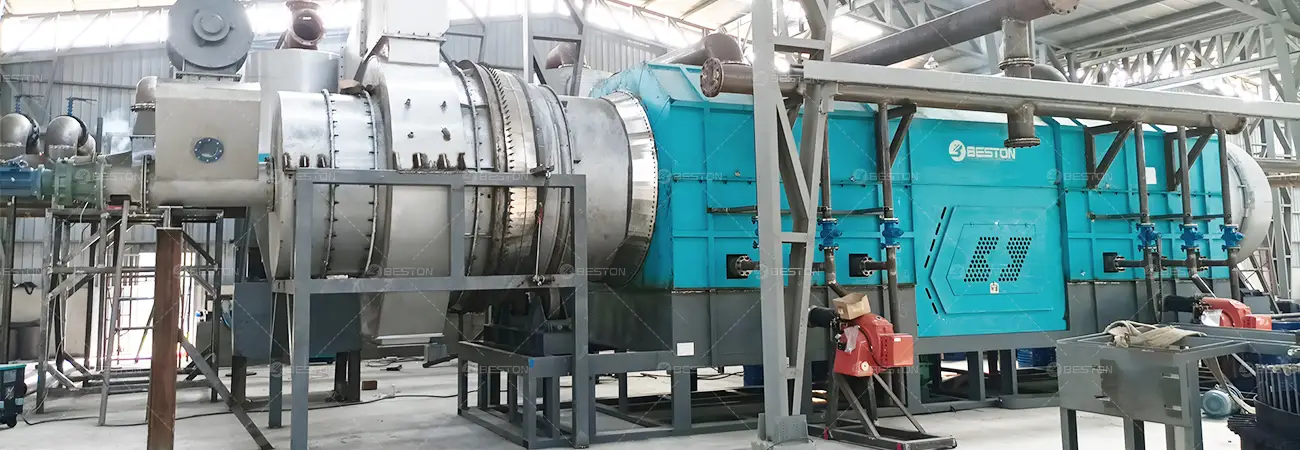

The design of the pyrolysis reactor significantly impacts the efficiency of sawdust conversion into biochar. There are various types of pyrolysis reactors, including fixed-bed, fluidized-bed, and rotary kilns, each with its advantages and limitations. The choice of reactor design depends on factors such as feedstock volume, desired throughput, and the specific characteristics of the sawdust being processed.

A well-designed reactor ensures uniform heating, minimizes energy losses, and maximizes heat retention, all of which contribute to an efficient pyrolysis process. Continuous charcoal machine is generally preferred for large-scale operations due to their ability to process sawdust consistently and efficiently. These systems maintain a continuous feed of material into the reactor, minimizing downtime and maximizing productivity.

Carbon Footprint and Environmental Considerations

One of the primary benefits of sawdust biochar production is its role in carbon sequestration. The pyrolysis process locks carbon in a stable form, preventing its release into the atmosphere as carbon dioxide. This makes biochar a valuable tool in mitigating climate change. However, the carbon footprint of the pyrolysis process itself must be carefully considered. The energy required to run the pyrolysis system and the emissions from the byproducts must be minimized to ensure the overall environmental benefit of the operation.

To reduce the environmental impact, it is recommended to utilize renewable energy sources for powering the pyrolysis plant. Integrating waste heat recovery systems and optimizing reactor design can also reduce energy consumption and improve the overall sustainability of the process. Additionally, monitoring emissions and implementing appropriate air filtration and gas cleaning systems ensures compliance with environmental regulations and minimizes pollution.

Market Applications and Economic Viability

Biochar derived from sawdust has numerous applications, particularly in agriculture. It is widely used as a soil amendment to improve soil fertility, water retention, and microbial activity. Biochar’s ability to enhance soil structure and reduce soil acidity makes it highly beneficial for a variety of crops. As the demand for sustainable agricultural practices increases, the market for biochar is expected to grow, driving the economic viability of sawdust biochar production.

Moreover, biochar can be used in environmental remediation, water filtration, and as a component in construction materials. The diverse range of applications opens up several market opportunities for biochar producers. However, the economic success of the production process depends on the efficiency of the pyrolysis plant, the cost of feedstock, and the market demand for biochar and its byproducts. Efficient plant operation, combined with effective marketing strategies, can ensure long-term profitability in this growing industry.