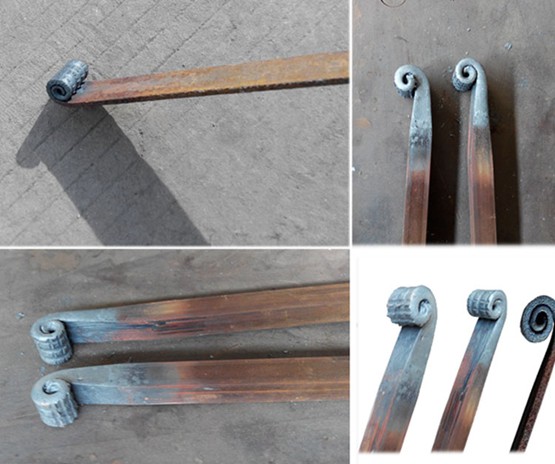

These are very unique machines that are designed to work with wrought iron. There is a coil that can superheat the metal. Once it is heated, it will be very malleable, and then can be placed into the coil aspect of the machine. This will allow the metal to be spun into a spiral, a design commonly seen on wrought iron products. This is one of the times where the metal needs to be heated up because of the tight turns that are made with the coil using the wrought iron bars that will be used. Let’s look at the working principle of the electric make coil machine, and then show you where to get these four reasonable prices from different companies across the world.

How Do Electric Make Coil Machines Work?

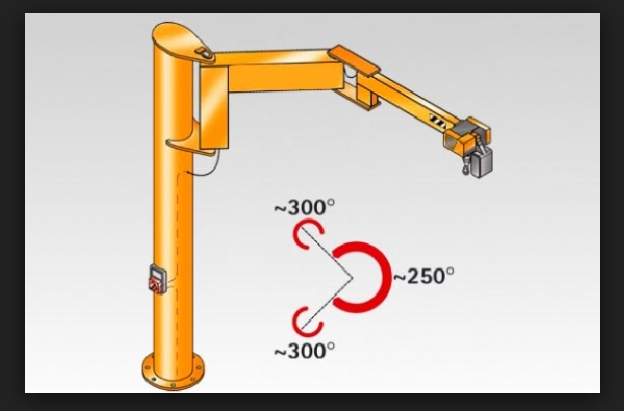

These machines are very unique in that they are able to do to completely separate functions. First of all, the metal is placed into what looks like a coil where it will be superheated within a few seconds. This is usually driven by an electric motor which is allowing the coil to get the metal hot. The second component of this machine is a mechanical machine which is often driven by electronics or hydraulics, which will allow the coil to be created.

Are There Different Types?

There are several different types that you can get, primarily because there are different companies that make these machines. Some of them are very small, designed to be worked by a single individual where production is not really a large factor. Others are very efficient at not only heating metal, but quickly making the spirals, and sometimes this process can be automated. They are typically housed on top of a workstation, allowing them to be easily operated in a safe manner, and capable of producing many different coils http://ellsenwroughtironmachine.com/electric-make-coil-machine-metal-craft/ every hour. Some of the machines that you will find will have different characteristics and features which we will discuss next.

Features Of Electric Making Coil Machines

The features that you should look for on these machines include a fluid driving device built within. It should be easy to use, and capable of producing batch quantities of the coils with a high degree of consistency. Additionally, if you are working with a machine that has much more advanced components, it’s going to have a lower working noise and will be very easy to take care of. This can be used in conjunction with many other machines that are used for wrought iron including an iron pattern bender, a metal twisting machine, and everything else that you will need in order to create the products that you sell.

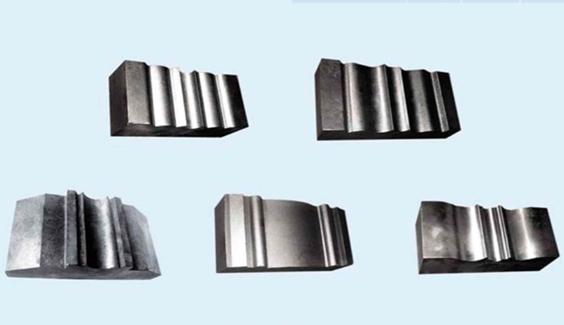

Most of these that are highly coveted come from one or two specific companies, some of which are selling their products from overseas. These leaders in the ornamental industry are also creating other wrought iron products including fishtail coining machines, and embossing machines, all of which are necessary for a wrought iron business to create and produce products that you see in stores today. Ellsen offers various wrought iron machines. Click here http://ellsenwroughtironmachine.com/ to know more.