Enhancing Safety Measures in Oil Sludge Pyrolysis Plant

In the intricate realm of industrial operations, the management of hazardous materials demands an unwavering commitment to safety protocols. Oil sludge pyrolysis plants, designed for the thermal treatment of oily waste, stand as crucial contributors to environmental sustainability. However, the inherent complexities of such facilities necessitate a meticulous approach to safety enhancement.

Understanding the Dynamics

Oil sludge pyrolysis plant, by virtue of their operational intricacies, require a multifaceted safety framework. The amalgamation of high temperatures and volatile substances accentuates the need for proactive measures. Employing cutting-edge technology is essential, coupled with a comprehensive understanding of the nuanced processes unfolding within these facilities.

Thermal Reactor Integrity

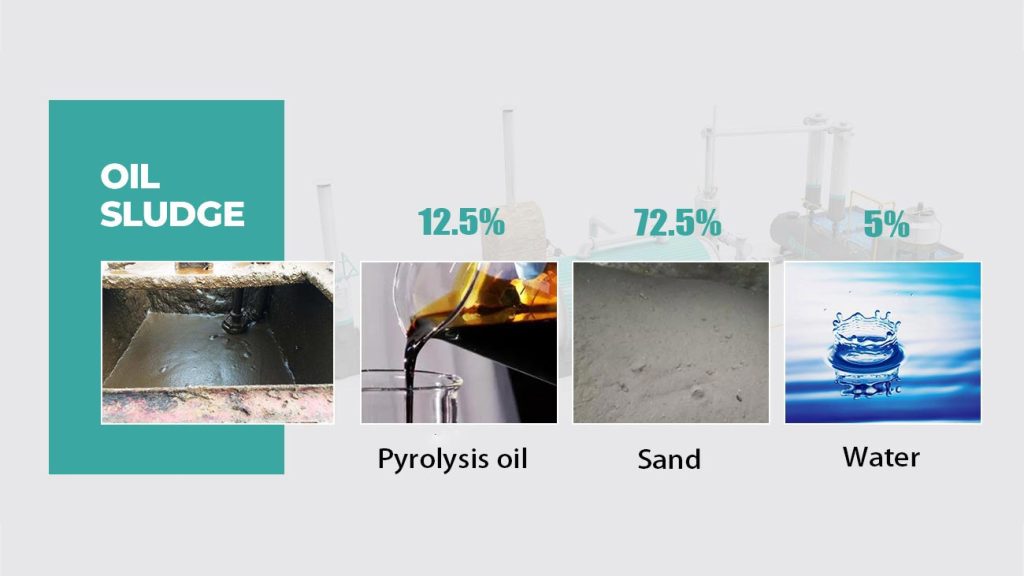

Ensuring the integrity of the thermal reactor is paramount in mitigating potential risks. The oil sludge pyrolysis plant relies on controlled thermal decomposition to convert hazardous waste into valuable resources. Regular inspections, utilizing advanced non-destructive testing methodologies, guarantee the structural soundness of the reactor, preventing potential leakages or ruptures.

Real-time Monitoring Systems

The advent of real-time monitoring systems represents a paradigm shift in safety protocols. These sophisticated systems leverage sensors and data analytics to provide instantaneous feedback on crucial parameters such as temperature, pressure, and gas composition. This proactive approach allows for swift intervention in the event of anomalies, averting potential disasters.

Operator Training and Competence

Human factors play a pivotal role in the safety equation of oil sludge pyrolysis plant. Operator training programs must be meticulous, emphasizing not only routine tasks but also emergency response scenarios. A well-trained operator, equipped with the knowledge of the plant’s intricacies, serves as the first line of defense against potential hazards.

Emergency Response Drills

Conducting periodic emergency response drills is indispensable. Simulating various scenarios enables operators to hone their decision-making skills under duress. Evacuation procedures, containment strategies, and communication protocols should be ingrained in the operator’s psyche, fostering a culture of preparedness within the facility.

Environmental Impact Mitigation

Beyond the immediate safety concerns, oil sludge pyrolysis plants must address the potential environmental repercussions of their operations. Robust safety measures should extend to waste handling and disposal, ensuring that the by-products of pyrolysis do not pose a threat to ecosystems.

Waste Containment and Treatment

Efficient containment and treatment of residual waste underscore the commitment to environmental stewardship. Utilizing advanced separation technologies, such as centrifugation and membrane filtration, facilitates the extraction of valuable resources from residual sludge while minimizing the ecological footprint.

Emission Control Systems

The combustion processes intrinsic to oil sludge/tyre/plastic pyrolysis process generate emissions that demand meticulous control. Implementing state-of-the-art emission control systems, such as electrostatic precipitators and scrubbers, ensures compliance with stringent environmental regulations. This not only mitigates the impact on air quality but also enhances the overall sustainability profile of the facility.

Regulatory Compliance

Navigating the intricate web of regulatory requirements is a non-negotiable facet of oil sludge pyrolysis plant operations. Compliance not only safeguards against legal ramifications but also reflects a commitment to responsible industrial practices.

Continuous Compliance Audits

Conducting regular compliance audits, guided by both national and international standards, ensures that the facility adheres to the latest safety and environmental protocols. This proactive approach minimizes the risk of unforeseen regulatory issues, fostering a harmonious relationship between the facility and regulatory authorities.

Technological Upgradation for Compliance

In an era of dynamic regulatory landscapes, technological upgradation is an imperative. Oil sludge pyrolysis plants must invest in cutting-edge technologies that align with evolving safety and environmental standards. This anticipatory approach not only averts regulatory pitfalls but also positions the facility as an industry leader in responsible waste management.

Conclusion

The confluence of safety measures within oil sludge pyrolysis plants encapsulates a holistic approach. From the meticulous inspection of thermal reactors to the implementation of real-time monitoring systems, and from operator training to environmental impact mitigation, each facet plays a crucial role in enhancing overall safety. By embracing a commitment to compliance and technological evolution, these facilities can navigate the intricate landscape of hazardous waste management with both efficacy and responsibility. Find Beston Group for batch or continuous pyrolysis plant.