Costs and Advantages of Plastic Recycling Pyrolysis Machines

Plastics or tyre may be generally defined as synthetic or semi-synthetic organic materials that are malleable and can be molded into a diverse range of solid objects, and they are characterised by their ability to deform irreversibly without breaking. Most plastics or tyre are organic polymers of high molecular mass that derive from petrochemicals and a large majority of them are synthetically-created to suit the everyday needs of humans. The plastic recycling machine is an effect way to deal with this problem. Here to get qualified waste tyre recycling plant.

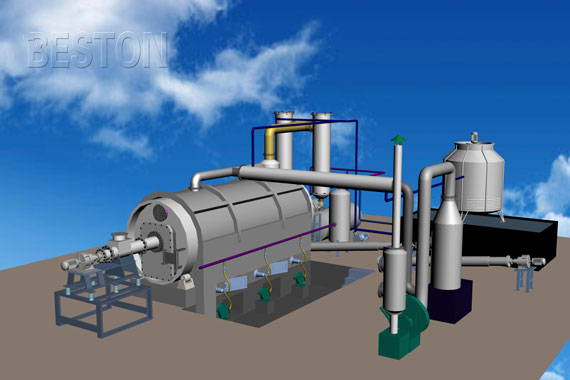

Plastic-recycling Pyrolysis Machines

Plastics are used in a wide variety of products ranging from automobiles, toys, packaging containers, furniture, plumbing and in the medical field due to their relative inexpensiveness, versatility, ease of manufacture and imperviousness to water. However, a downside to this durability and non bio-degradability is that they accumulate easily as pollutants that negatively impact the health of wildlife and their habitats in the natural environment. It is therefore important to dispose of used plastics in a sustainable and eco-friendly manner, and one important way of doing this is to recycle them through pyrolysis plants. If you look for a fair tyre pyrolysis plant cost, consult Beston for more info.

Pyrolysis is the chemical decomposition of condensed organic substances (such as plastic) by heating. Pyrolysis involves taking long-chain polymer molecules and breaking them up into shorter chains through extensive heating and pressure, a process of plastic recycling which closely mimicks the Earth’s natural processes that decompose carbon into oil, albeit in a closed system using intense heat in a shorter period of time. Pyrolysis of plastic waste does not involve the use of oxygen and typically produces a liquid-like product (known as pyrolysis oil) that may be readily stored, transported or advantageously used, after further refinement, as diesel or jet fuel.

Pyrolysis technology also has many unique advantages from an industrial perspective. For instance, it involves lower reaction temperatures of around 350 to 475 degrees celsius and a much shorter reaction time of 15 to 45 minutes compared to more traditional heating or decomposition methods which helps to lower operating costs and machine maintenance. Get the detailed waste plastic recycling plant cost here.

Pyrolysis also employs the use of a two-step energy recovery system that ensures an energy efficiency of above 80%. The machinery involved is also very self-sufficient in terms of energy expenditure since no external fuel is required for heating under normal operating standards. The excess gas released may also be used to run an electricity generator or may be re-directed to a furnace. Most pyrolysis machines come equipped with an effective scrubbing system to reduce harmful emissions and an operational pressure of below 300mmWC to lower the risk of fire or pressure-related hazards. The waste products of pyrolysis are typically much less harmful small molecules of oil, sludge and carbon blocks. We will show you the more information here.