Exploring Coconut Shell Charcoal Making Process

In many places around the world, agricultural waste, like palm kernel shells, straw, sawdust, rice hulls, peanut shells and coconut shells, is used as livestock feed or dirty heating fuel. However, thanks to carbonization technology, it is now possible to convert biomass waste into charcoal. The coconut shell charcoal production, for instance, is now very easy due to the invention of the various carbonization machines. With the right biochar production equipment, it is possible to carry out the process without releasing any toxic pollutants into the atmosphere.

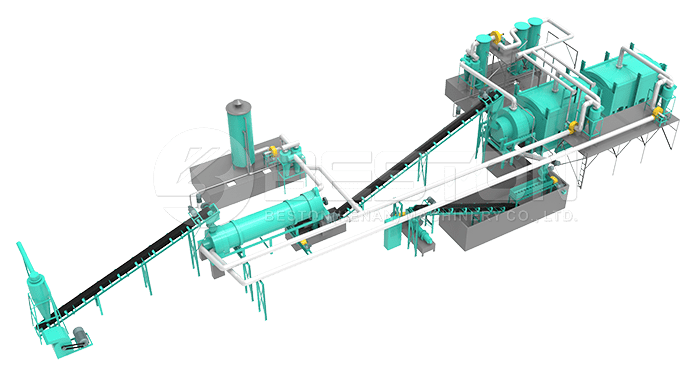

Charcoal Making Plant in Turkey

Coconut shell charcoal making machines are beginning to become more economically viable investments for businesses of all sizes. You will see them in many waste processing facilities around the world. Investing in such a machine can be a very profitable venture with great annual returns. Arguably one of the most prolific manufacturers in the charcoal making machine industry is Beston Group China. The manufacturer creates a wide range of biomass carbonization furnaces which can be used to process all types of biomass waste, including oil sludge waste and municipal waste.

To explain more about how the charcoal making machine works, let’s look at how coconut shell waste is converted into charcoal. To start with, the shells are ground up into tiny particles. Next, the shell waste needs to go through a drying machine if the moisture content exceeds ~15%. The reason for this is that if the moisture content of the coconut shell waste is high, inefficient carbonization will happen due to the steam produced. For high-grade coconut shell charcoal production, as much moisture as possible should be removed from the shells prior to them entering the carbonization machine.

Charcoal Making Machine Design

Once the biomass waste has been prepared for the reactor, it is transported into the reactor via a conveyor belt setup. The biochar reactor furnace reaches extremely high temperatures which convert the coconut shell waste into charcoal. In a typically charcoal making plant, all of the gas produced will be used to power the carbonization furnace, thus reducing fuel costs.

In some countries, there are very strict regulations on emissions, so the modern charcoal making machine is fitted with advanced dedusting systems. Such systems clean all plant emissions and ensure no pollutants are released into the atmosphere.

The final products of coconut shell carbonization include high carbon charcoal and combustible gas. Since the biochar produced has a high carbon content, it is a great clean-burning fuel. As a result, it is perfect for the production of BBQ briquettes. The biochar produced also makes a great soil additive and can lead to increases in crop yields. The reason the biochar is a good soil addictive is that it has a rich micronutrient profile and antimicrobial properties.

There are lots of coconut shell charcoal making machine for sale, so it’s important to know what factors to look out for. Some of the key features to compare include machine operating pressures, hourly feeding capacity, cooling method, price, reactor size, total power, lifespan, and raw material compatibility.