How to Choose the Best Pulp Molding Machine — BESTON Machinery

Molding has been around for over a century. Molding allows producers to create bespoke designs for a variety of applications, including art, packaging, and automotive parts. The 21st century however brought something new to the table — think value, raise the sustainability bar. As a result, garbage, particularly waste paper, is used to make a variety of end goods. This is made possible by pulp molding machines.

Cartones del Huevo

What is a Pulp molding machine?

It’s a machine that uses waste paper to create egg trays(utiliza maquina para hacer bandejas de huevos), coffee cup trays, packaging cartons, and fruit trays. It’s also known as a paper molding machine because it employs waste paper and water as feedstock. This machine turns waste paper into a valuable resource.

Top 5 Things to Consider When Purchasing a Pulp Molding Machine

1.Ease of Use

Different functioning modules are used by different machines. Look for a machine with a modular design that allows for a variety of configurations and is simple to install and operate. Furthermore, a good design will provide a low failure rate during operation and after operations. BESTON engineers are noted for their precision and accuracy in their work, as well as a low failure rate in their machines.

Máquina para Hacer Cartones del Huevo

2. Design

What is the configuration of the pulp molding machine?(diseño de BESTON) How complex is it? The cost of a higher-leveled configuration is usually higher. The price will rise in tandem with the increased output and capacity. The price of a plastic forming mold, for example, is less than that of a metal mold. Furthermore, an integrated pulping system will be more expensive than a typical pulping system. A four-sided forming machine will also be more costly than a single-sided forming machine.

3. Scale of Production

Different manufacturing capacities are available depending on your requirements. The capacity of small pulp molding machines ranges from 1000 to 1500 pieces. The next machine is a semi-automatic pulp molding machine(https://www.bestoneco.com/maquina-para-fabricar-cubetas-de-huevos/). It can produce between 2000 and 2500 pieces each day. The automatic pulp molding machinery, which has a big capacity to create paper trays in a day, is the last and highest on the list. Because of the high volume of paper tray production, it is better for large-scale production.

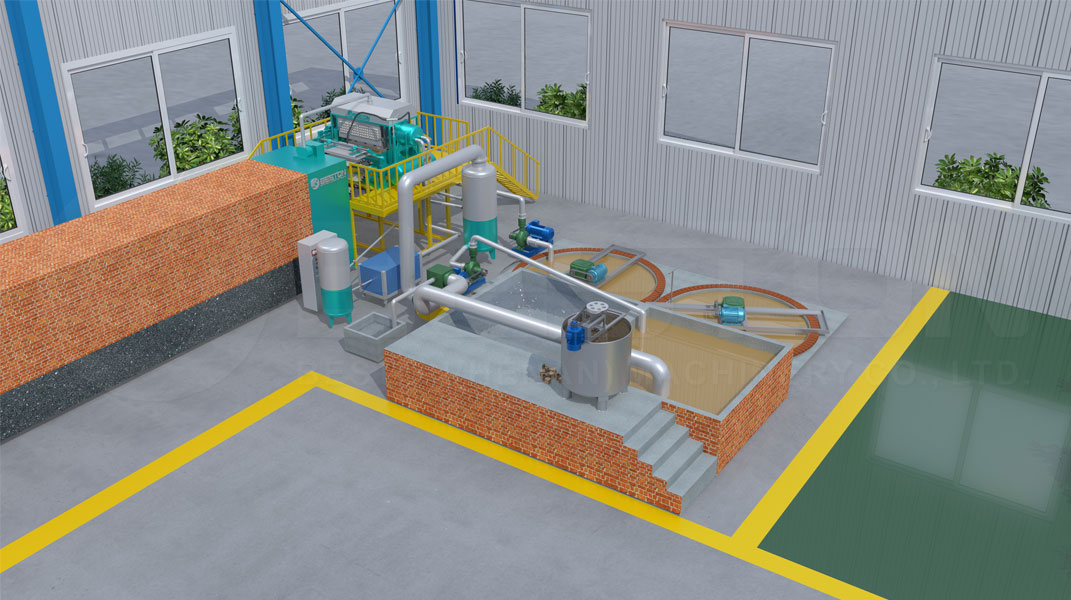

4. Drying System

Furthermore, the drying systems are set up differently. A natural, brick drying system or a metal drying system could be used. The first is the most basic, while the last is the most complicated. The natural drying system can be used in a dry region with plenty of sunshine, wind, and high temperatures.

5. Environmentally friendly design

To begin, the pulp molding machine produces biodegradable paper molded trays. Paper trays are becoming more popular as a result of the ban on plastic in many countries. Furthermore, the pulp molding production process is free of pollution

BESTON Pulp Molding Machinery

BESTON, being one of China’s most dependable pulp molding machine(maquina para hacer maples de huevos) manufacturers, has a strong ability to export the machine all over the world. BESTON has consumers and fans from all over the world, including Asia, Africa, South America, Europe, and many others. We’ve gained widespread recognition among molded pulp manufacturers all around the world. Contact us to get the best deal on the market!