When it comes to embracing sustainable practices and efficient resource management, the pyrolysis plant emerges as a compelling solution. These innovative facilities are designed to convert waste materials into valuable products, all while minimizing environmental impact. In this in-depth exploration, we delve into the intricacies of the pyrolysis plant cost, dissecting the factors that influence it, and evaluating the economic and environmental implications.

Unpacking the Pyrolysis Process

Before delving into the pyrolysis plant cost, it’s imperative to comprehend the core mechanism of a pyrolysis plant. Pyrolysis is a thermal decomposition process that occurs in the absence of oxygen. This transformative process converts organic materials, such as plastic, tires, or biomass, into valuable end-products, primarily consisting of pyrolysis oil, gas, and char.

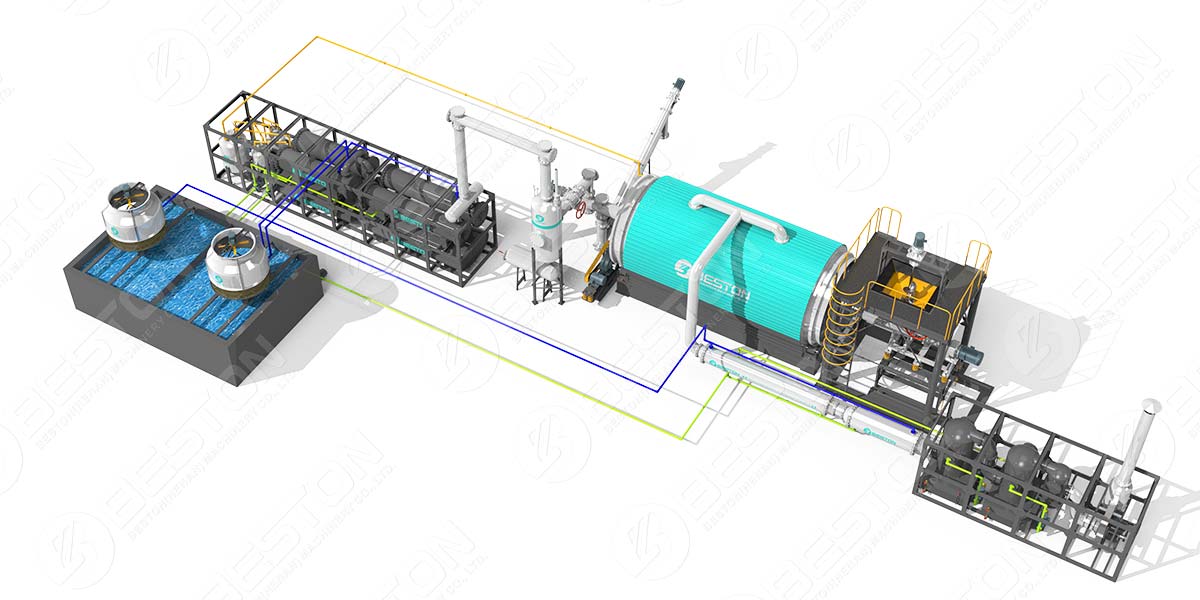

The operation of a pyrolysis plant involves the following key steps:

- Feeding: Waste materials are introduced into the reactor chamber of the plant.

- Heating: The waste materials are heated in the absence of oxygen, triggering the pyrolysis process.

- Pyrolysis: The high temperatures cause the organic materials to break down into gases, liquid pyrolysis oil, and solid char.

- Condensation: Gases produced during pyrolysis are condensed into valuable products, such as pyrolysis oil and gas.

- Collection and Separation: The resulting products are collected, separated, and further processed for various applications.

Layout of BLJ-16 Pyrolysis Plant

Factors Influencing Pyrolysis Plant Cost

The cost of setting up and operating a pyrolysis plant can vary significantly due to several influencing factors:

- Plant Capacity: The size and capacity of the pyrolysis machine for sale play a pivotal role. Larger plants with higher processing capacities generally entail more significant upfront costs.

- Technology and Equipment: The choice of technology and the quality of equipment utilized can impact both initial investment and operational costs.

- Feedstock Type: The type and quality of the feedstock (waste material) can affect processing efficiency and, consequently, operational costs.

- Location: Geographic location can influence costs associated with labor, permits, and utility expenses.

- Regulations and Compliance: Adhering to environmental regulations and obtaining permits can add to the overall cost of operation.

- Maintenance and Operating Costs: Regular maintenance and operational expenses, including energy consumption, must be factored into the cost analysis.

- Market Demand: The demand for end-products, such as pyrolysis oil or char, can influence the economic viability of the plant.

The Economics of Pyrolysis Plants

While the pyrolysis plant cost may seem substantial upfront, it is essential to consider the economic benefits in the long run:

- Resource Recovery: Pyrolysis plants enable the recovery of valuable resources from waste materials, reducing the need for raw materials and contributing to resource efficiency.

- Energy Generation: The pyrolysis process generates heat and gases that can be used for energy production, potentially offsetting operational costs.

- Market Value: The products obtained from pyrolysis, such as pyrolysis oil, have market value and can be sold for various industrial applications.

- Waste Reduction: Pyrolysis helps divert waste from landfills and incineration, reducing disposal costs and environmental impacts.

- Carbon Credits: In some regions, tyre pyrolysis plant may be eligible for carbon credits, providing additional revenue streams.

Sustainability and Environmental Benefits

Beyond the economic considerations, pyrolysis plants offer substantial environmental advantages:

- Waste Diversion: By converting waste materials into valuable products, pyrolysis contributes to waste reduction and landfill diversion.

- Emissions Reduction: The controlled pyrolysis process minimizes harmful emissions compared to traditional waste disposal methods.

- Resource Conservation: Pyrolysis promotes the efficient use of resources, mitigating the need for virgin materials.

- Clean Energy: The generation of renewable energy from pyrolysis gases aligns with sustainability goals.

Conclusion

In the pursuit of sustainability and responsible resource management, the waste plastic pyrolysis plant stands as a compelling solution. While the pyrolysis plant cost may pose an initial investment challenge, its economic and environmental benefits make it a sound choice for businesses and communities looking to reduce waste, generate valuable resources, and minimize their environmental footprint.

As technology advances and regulatory frameworks evolve, the economics of pyrolysis are becoming increasingly favorable. With a commitment to innovation and sustainable practices, pyrolysis plants play a pivotal role in shaping a more environmentally conscious and economically viable future.