In the construction and lumber industries, sawdust is usually considered a waste product. However, this could not be further from the truth as there are numerous great techniques that can be implemented to reduce waste. One of the more efficient ones is using the charcoal making machine.

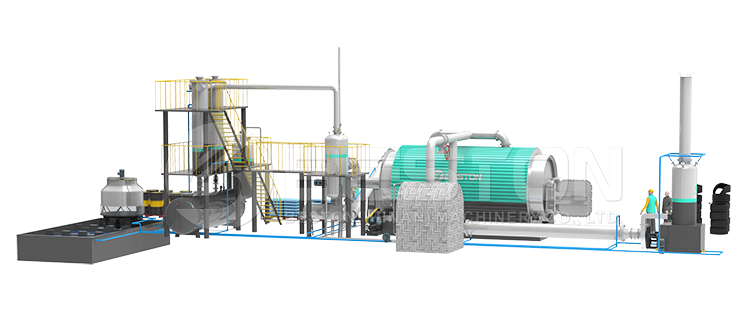

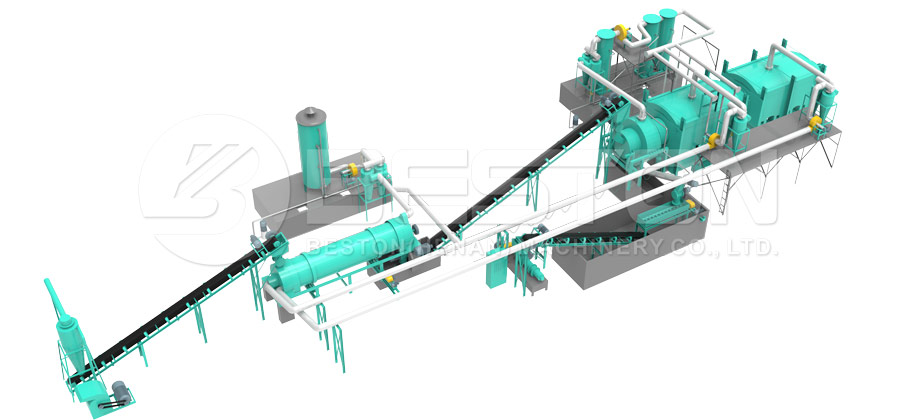

You’ll come across machines that are specifically designed for this purpose. They take conventional sawdust, dry it, and transform it into charcoal briquettes that can be used for an array of things. This is a substantially better use of sawdust compared to discarding it. Trees are a limited resource in this day and age, and so, it’s imperative to make use of the parts in order to avoid waste. Investing in one of these incredible machines is an excellent way to turn huge sawdust volumes into charcoal.

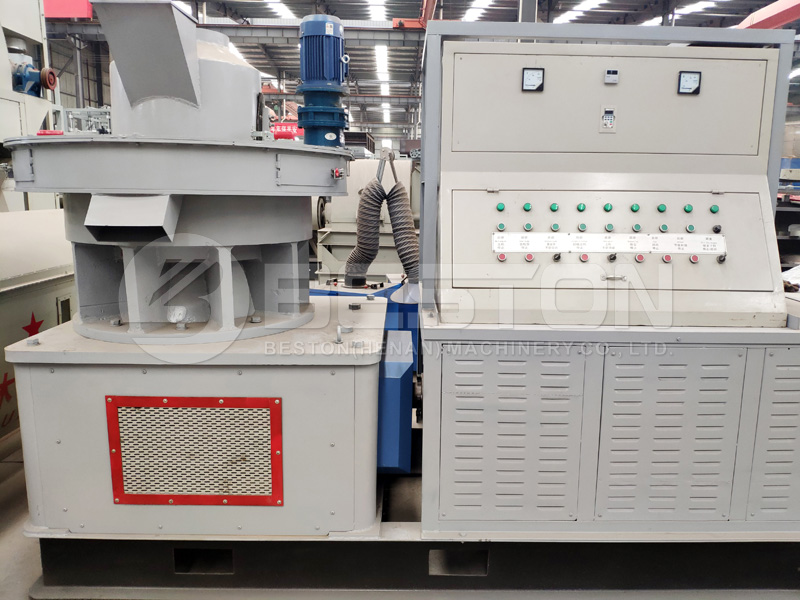

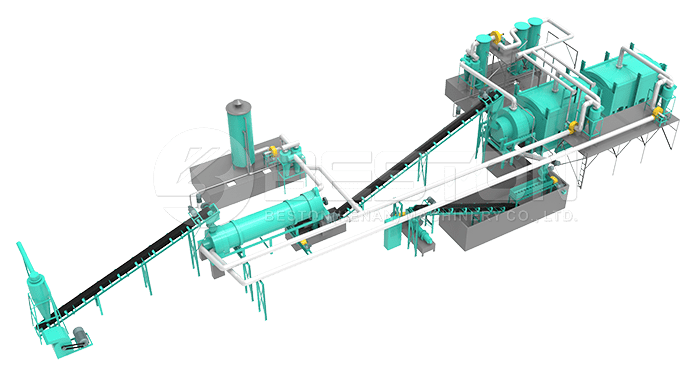

Charcoal Making Machine

However, to ensure you get the right machinery for your needs, there several things to keep in mind including the following:

The Efficiency

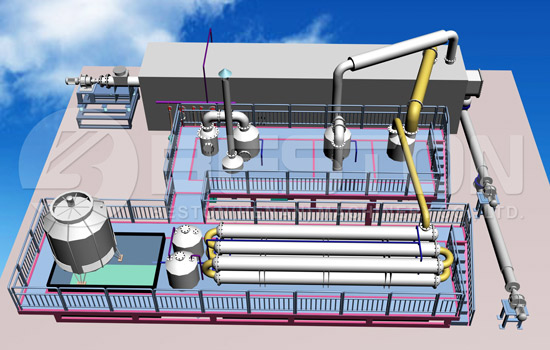

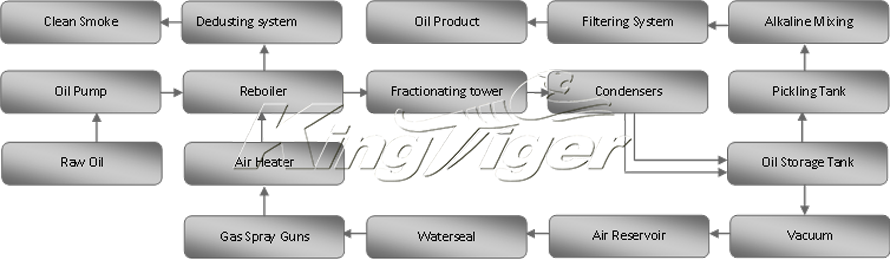

If you are looking to make a profit, efficiency is a vital factor. When browsing charcoal making machines, you’ll want to consider both their workflow and energy efficiency. When it comes to energy efficiency, you’ll want to go for machinery that can be partially powered by the gas released from the process of making charcoal. This can help reduce the total energy required to run the machinery, thus keeping the operational expenses down. Click here to know more: https://bestonpyrolysisplant.com/.

Also, you’ll need to look for charcoal making machine that relies on the fewest steps. This is important in reducing the number of workers required to run the machinery while speeding up the overall workflow.

Some charcoal manufacturing machinery are only designed to handle sawdust only, while others can convert an array of other materials into charcoal simultaneously. For instance, you’ll come across machines that are made for not merely working on sawdust, but on other forms of biomass including rice husks, coconut shells, municipal solid waste, etc. Choosing a charcoal making machine that gives you more flexibility depending on how you run your business is certainly imperative.

The Price

In order to keep your business profitable, you need to buy wood chips charcoal making machine that’s within your budget and in the affordability category. In this scenario, it means hunting for a machine that is not only affordable but can help you meet your production needs.

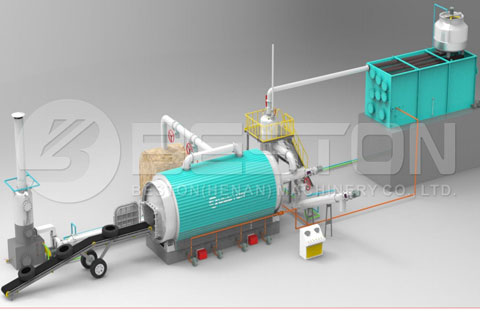

Charcoal Making Plant to Ghana

The Maintenance

Ideally, the machine that you ultimately decide to buy should be easy to maintain as it is to use. This way, you won’t have to dedicate a lot of time and energy to ensure it runs optimally. Instead, you’ll be able to pay attention to producing more quantities of charcoal, thus boosting your profits.

When buying a charcoal machine, whether for sawdust or any other material, ensure you consider all the factors mentioned above. By addressing these questions, you’ll be able to determine whether or not the machinery will be able to meet your needs. It is worth taking the time to shop around and compare all available options. By doing so, you’ll certainly come across a machine that will help you produce charcoal in the most affordable way. More videos on the machine here: https://www.youtube.com/channel/UCXAIC6Y1Jb7FCcKw87LJZHg/.