Selecting a reliable pyrolysis plant manufacturer is fundamental for businesses looking to turn waste tyres into valuable resources like fuel oil, carbon black, and steel wire. With numerous manufacturers offering a wide range of options, choosing the right supplier requires careful consideration of several key factors, including technology, production capacity, and environmental compliance. This guide provides insight into what to prioritize when choosing a tyre pyrolysis plant manufacturer.

Assessing Technological Expertise

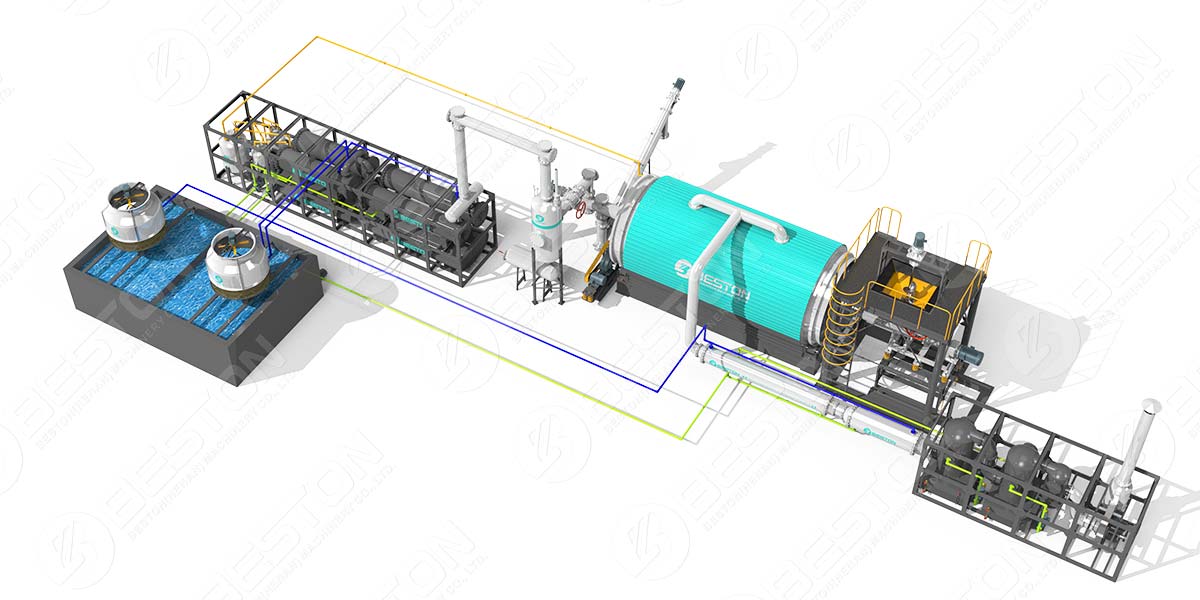

One of the primary considerations when selecting a waste tyre pyrolysis plant supplier is their level of technological expertise. Modern pyrolysis plants require advanced systems to ensure efficient and environmentally responsible processing. Key features to look for include:

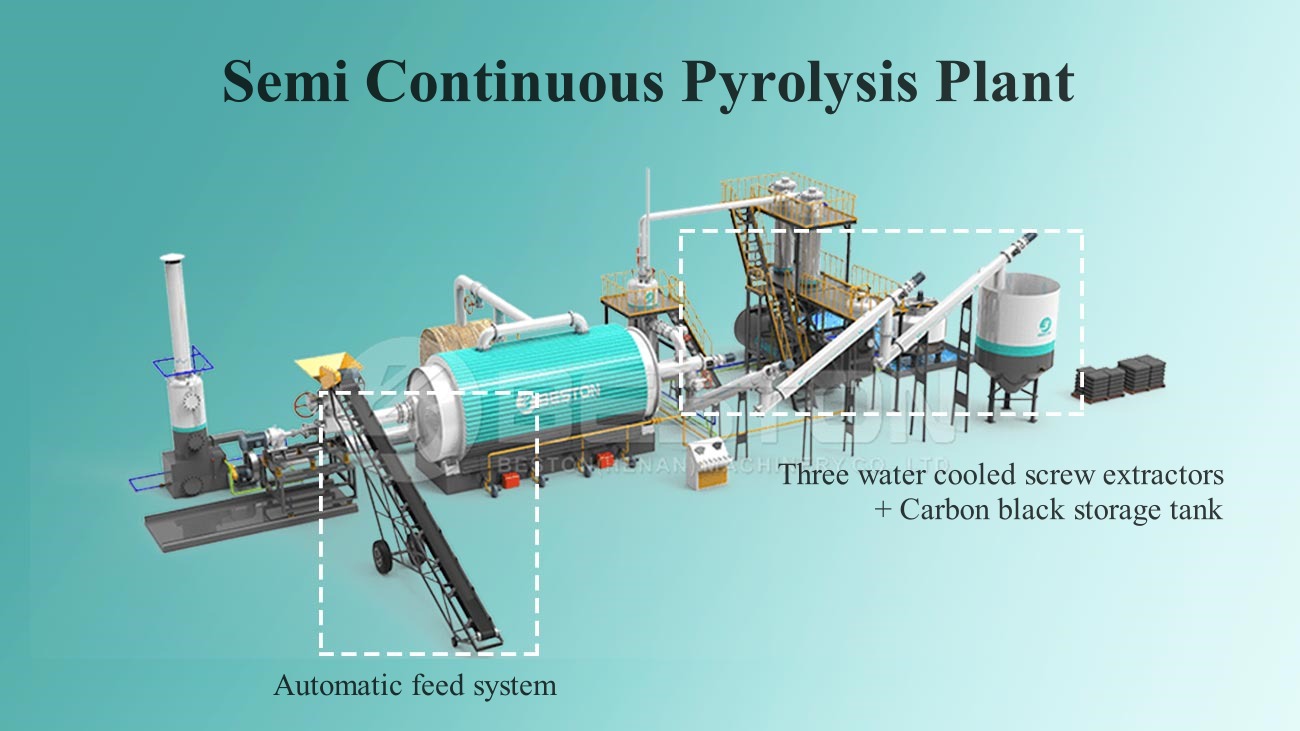

- Continuous Operation Technology

A manufacturer offering continuous tyre pyrolysis technology allows for uninterrupted operation, which can significantly enhance production capacity and reduce downtime. Continuous systems also require less manual intervention, lowering labor costs and improving operational efficiency. - Temperature Control and Heat Exchange Efficiency

Pyrolysis is a high-temperature process, and the ability to maintain precise temperature control is essential for quality output. Choose a manufacturer with a proven heat management system that minimizes energy consumption while maximizing the yield of fuel oil and other by-products. - Advanced Emission Control Systems

Since pyrolysis can produce hazardous emissions, look for a manufacturer who prioritizes environmental protection. Systems like dust scrubbers, desulfurization, and catalytic converters help minimize pollutants, ensuring compliance with environmental regulations and contributing to a safer, cleaner production process.

Reputation and Market Experience

A pyrolysis plant manufacturer with extensive market experience and a solid reputation is more likely to deliver reliable, high-quality equipment. Evaluate a manufacturer’s industry standing by reviewing customer testimonials, case studies, and certifications. Reputable manufacturers often have a portfolio of successful installations and long-term client relationships, which indicates their reliability and ability to provide ongoing support.

Industry Certifications

Check if the manufacturer holds relevant certifications, such as ISO 9001 for quality management and ISO 14001 for environmental management. Certifications reflect the manufacturer’s commitment to quality standards and regulatory compliance, adding an extra layer of assurance.

Post-Sales Support and Service Network

Post-sales support can be critical to the long-term success of your pyrolysis plant. A manufacturer with a strong service network and a well-trained support team can quickly address any technical issues that arise, reducing downtime and operational costs. Many tyre to fuel recycling plant manufacturers provide training programs for the client’s operators, helping ensure the efficient and safe use of the pyrolysis plant.

Scalability and Production Capacity

Evaluate your expected production output and confirm whether the manufacturer’s equipment can meet this demand. Some manufacturers offer modular systems, allowing businesses to scale production as demand grows. This modular design is particularly beneficial for enterprises that intend to expand their operations or diversify into different pyrolysis materials in the future.

Customization Options

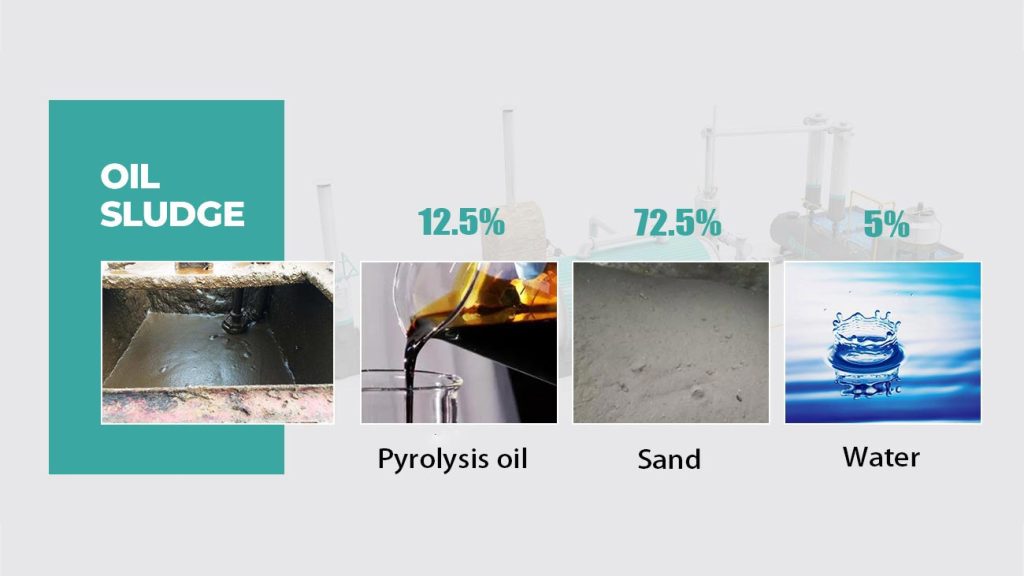

Different businesses have specific requirements, depending on local waste streams and regulatory conditions. A manufacturer that offers customization options for reactor size, feed systems, and environmental controls can help tailor the plant to meet unique operational needs. This flexibility can optimize the processing efficiency and ensure that the plant aligns with site-specific requirements.

Financial Considerations and ROI

Cost is an inevitable factor in selecting a tyre to oil plant manufacturer, but it’s important to evaluate both initial expenses and potential long-term savings. Some manufacturers may offer equipment with a lower upfront price but higher operational costs due to inefficiencies or limited lifespan. Look for a manufacturer that provides a balance of quality and affordability.

Maintenance and Operational Costs

Discuss maintenance requirements with the manufacturer to understand ongoing costs. Reliable manufacturers often design their plants with durable materials and easy-to-replace components to simplify upkeep. A well-maintained pyrolysis plant can last for decades, offering a strong return on investment (ROI).

Warranty and Payment Options

Inquire about the manufacturer’s warranty policies and payment terms. Warranties indicate the manufacturer’s confidence in their product’s durability. Flexible payment options can make it easier to finance the purchase, reducing the upfront financial burden.

Compliance with Environmental Regulations

A pyrolysis plant manufacturer must adhere to both local and international environmental standards. Confirm that the equipment meets or exceeds relevant environmental regulations, particularly if your business operates in regions with stringent policies. Many manufacturers offer emission control technologies that can be adjusted to comply with evolving regulations, which may help protect your investment in the long term.

Summary

Choosing the right tyre pyrolysis plant manufacturer involves balancing technical performance, cost-efficiency, and compliance considerations. By assessing a manufacturer’s technology, reputation, scalability, and commitment to environmental protection, businesses can secure a solution that meets both current needs and future growth ambitions.