As a manufacturer at times it becomes tough for you to handle the waste tyres? On the other hand , you are committed to your environment as well. As a professional businessman, you want to utilize in the most useful way. In that respect you can convert the waste tyre to fuel oil. Obviously it gives you the best of both worlds. You can save the environment from pollution as well as to get the desired end product as well. Find more tire recycling plant here!

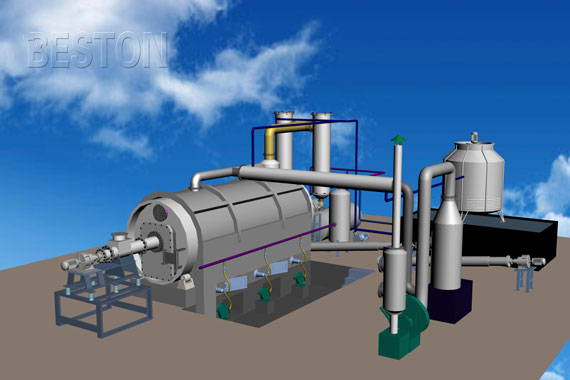

Waste Tires Into Fuel Oil Pyrolysis Plant

The Working Process of Waste Tyre Into Oil Machine

First you need to take the waste tyre and break that into small pieces of rubber. Then just put that into the reactor by the system of feeder. Ensure that the machine door is entirely sealed.

Now the reactor will start to heat the material. As soon as the temperature touches 500 degrees an oil is produced. Then this dense oil gas is segregated and it is left to liquefy. Eventually it settles in the oil container.

Then the gas which is lighter will move up to condenser, as liquefies will be preserved in the oil tanker.

The dedusting method is used to end the pollution caused from it.

Make sure to cool the reactor as the oil is released.

In the end, a trace of gas can be found, but make sure to release that to the environment as well. Click here to know more about Beston Company.

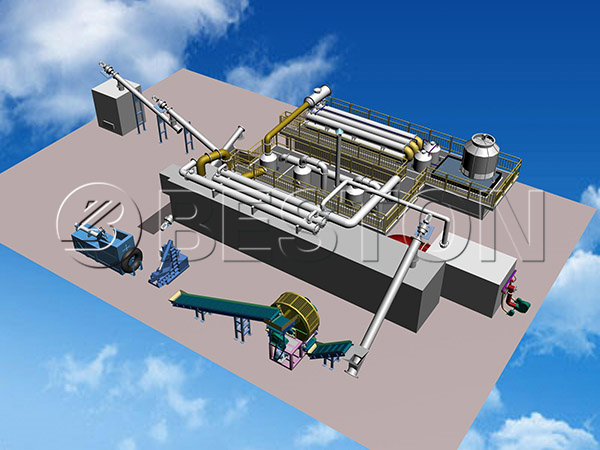

Tyre Pyrolysis Plant in Jordan

End product from tires to oil machine:

The tyre pyrolysis oil which is emitted as 45%;

Black carbon is generated as 30%;

Combustible Oil gas is produced as 10%;

Steel wire which is 15%.

What are the applications of the waste tyre pyrolysis plant in China?

You should note that it has multiple applications and extensively used for both commercial as well as industrial domains:

You can use it to produce electricity.

You can use it thoroughly to heat any type of material.

Most importantly the oil can be used for heating fuel.

Now you can enormously add this for serving the boiler and glass factories, steel mills, cement factories.

On the top of that, just note that it also serves at its best when used in the diesel industries. Get high-quality pyrolysis equipment for sale here.

Vital benefits;

You should see that the raw material used in the process is quite cheap.

You can recycle the waste tyres to the fullest but no end material leaves behind.

Most noteworthy, that the waste tyre to oil pyrolysis machinery involves no catalyst.

Apart from that you will get a competitive advantage in terms of price as well.

One more thing, it does not leave any negative impact on the environment. This is because it is completely safe and eco friendly. Get pyrolysis plant cost here.

Thus, you can rely on the process , therefore whenever you want to make your waste tyre to fuel oil pyrolysis machinery, just get hold of the powerful and enduring models. In addition to that, you should also comprehend the market price of each of the models. Undoubtedly this will give you the best turnover in the long run. And will draw outstanding profit to your business.