Moving people from point A to point B is a problem with a thousand different solutions. If you’re operating an amusement park or other major attraction, transportation is definitely not an insignificant problem. A lot of venues use trackless trains (использовать безрельсовый поезд) to meet some or all of their guest transportation needs. Considering a trackless train of your own? It’s a good idea to learn all you can about them prior to picking one. Here’s a general historical overview.

Trackless Trains Defined

A trackless train (один аттракцион паровозик безрельсовый) is, in the broadest sense, any multi-carriage vehicle that operates on rubber-tired wheels. This would include people carriers, trams, baggage trains, and other similar vehicles. When the specific term “trackless train” is used, though, it’s normally in reference to a vehicle designed to mimic the appearance of a steam train.

Small-Gauge Rail

“Miniature” railroads actually predate automotive vehicles by decades. They were frequently used in mines and other small-scale industrial applications. These sorts of trains were indelibly linked with a more recreational use when they started to appear in the earliest amusement parks.

Scaled down to suit younger passengers and shorter trips, these early trains differed from their bigger steam-powered brethren only in size. Although they were enormously popular with tourists, visitors, and park guests, they were also extremely expensive due to their need for dedicated tracks.

The Amusement Park Era

Modern technology soon solved the primary obstacle to the wider use of the amusement park train by adapting ordinary road-going vehicles to the purpose. Some of the earliest trackless trains were still steam-powered, and the surviving examples of this type are now attractions in and of themselves.

The Disney corporation has played a key role in popularizing the trackless train for amusement parks, fairs, zoos, and other recreational venues. While Disney parks are famous for more intensive transport systems (e.g. Disney World’s Monorail), they also make use of dozens of trackless trains in their parking lots and grounds.

Modern Trackless Trains

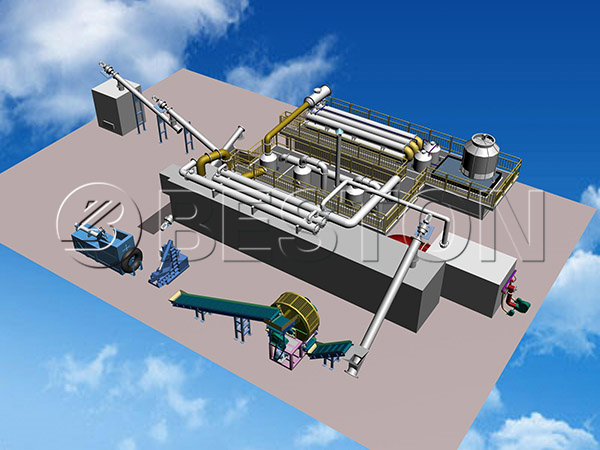

Today many different manufacturers (много различных производителей аттракционов) around the globe construct trackless trains to suit a variety of purposes. The smallest trains are suitable for rental use at parties and other special events, while larger versions are capable of putting in long hours of continuous work.

Modern trackless trains are usually powered either by electric batteries or an internal combustion engine (diesel or petrol) like that found in a truck. There are still a few manufacturers who create trackless trains that operate via steam power; these typically use propane as their fuel source.

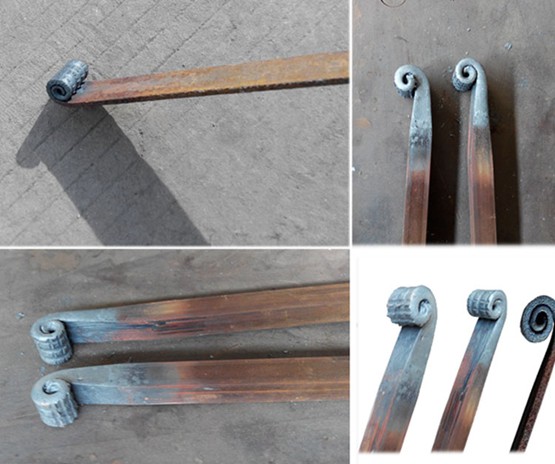

The amount of effort expended on decorating trackless trains varies greatly from manufacturer to manufacturer. The most economical models are frequently very standardized carts with a fiberglass shell wrapped around them. More expensive versions may make use of authentic materials like wood and metal, and in the most high-quality cases may be built using the same coachbuilding techniques employed on historical rail trains. View publisher site: amusementridesforkids.ru/

Today’s trackless trains are built on a decades-old legacy of technological innovation and refinement. This makes most of them highly reliable and affordable to operate. Maintenance and repair needs are usually quite modest, and a train that’s chosen to fit its job well is likely to provide many years of trouble-free service to your venue.

Get More Information: http://amusementridesforkids.ru/kupit-detskiy-attraktsion-parovozik-bezrelsovyy-attraktsion-poyezd/