You may now enjoy the excellent performance of the fruit tray creating machine – bring your life convenience. Have you strolled from one point to another looking for a convenient egg fruit tray creating machine? In any case, if these questions have been causing trouble whenever you think of them , it is clear you are in the right place. With no further consideration, this new packing machine in the market points at this molded pulp products. Presently, you may find apple tray in various points of the world with supermarkets and home included. The manufacturing process of this machine consists ;( raw materials pulping substances , drying packing and mold forming )The common raw material is usually waste paper and water. This machine not only sets free the glue addictive aspect but also makes use of the coloring . By the help of that glue characteristic this apple tray making machine turn into anti-water as the pigment accountable for yielding favorite colors. The apple tray making machine for sale can bring your life convenience.

Properties of this “Egg Tray Making” Machine

This egg tray making machine brings your life convenience given that it has these amazing properties. You can click here for more information on egg tray machine price in India. These properties include;

. Good protective and changeable quality

. Good functions of absorbing hydrophobic, water and insulation

. Well used in packaging fresh products because of good permeability

. General large production capacity

. Mass-produce all kinds of food container, trays

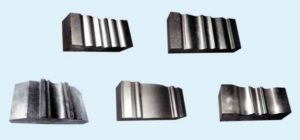

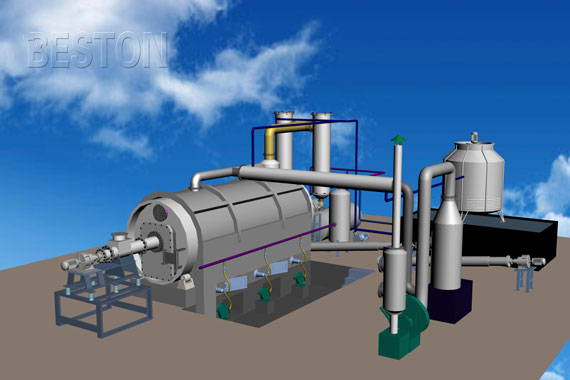

. Has a forming system ( includes; clean water pump, forming machine,air compressor , a vacuum tin, a forming mould, self absorbing pump, air container, transferring mould and vacuum pump.)

.Also has a pulp making system ( includes;a stirrer, a multi friction system,a pulp pump, a hydraulic pulper, pulp creating control system)

.Has a drying system (includes; blower, burner, conveyer, drying control system)

. Packing System, that is automatic loading and counting machine

.Uses waste paper as raw materials

Advantages of this egg tray making machine

There are several benefits of using this machine. Despite apple fruit tray creating machine -bringing your life convenience, it has several other advantages which include;

Economic

The forming system is designed to have the sprays and oil supply automatically. Hence this machine is created to save energy via heat absorption to ensure that only a little or no heat get wasted. The tray making machine needs low maintenance. Also it is affordable and gives you great returns.

Safety

The machine have been certified and tested to ensure that you have peace of mind when using it as it is safe. Also considering the high quality materials used in designing the machine, it is so easy to keep it in a good condition.

Efficiency

This machine is made in a way that allows it to perform very well. It is quick and fast in making the trays. Also you may request the manufacturer to customize your tray machine according to how many pieces of apple trays you are interested to make per day or per hour. See the how to make egg tray here.

Flexibility

These machines are flexible in that they can make various products. Some of this machines offer you an option to make apple trays with more than one layer.

Application

These machines are used to make products as egg or carton box and egg tray all from waste paper.

Our company also provides you with fully automatic paper egg tray machine with good quality and reasonable price.