If you have a small farm that is producing a minimal amount of eggs, you still need to have a way of protecting them. The cartons and egg trays that you produce can house them, allowing you to make deliveries. Even if you have a larger system, it is important to have proper egg tray machines up and running every single day. They can produce thousands of trays, all of which can be used, to keep up with the eggs that you are producing. To find an affordable small egg tray machine, let’s look at what your options are for finding one of these units.

Paper Egg Carton Machine

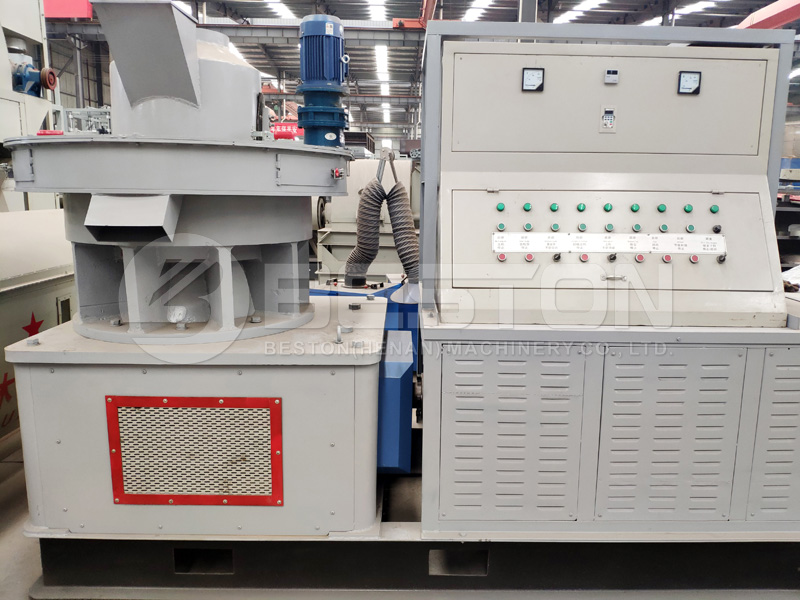

How Do These Egg Tray Machines Operate?

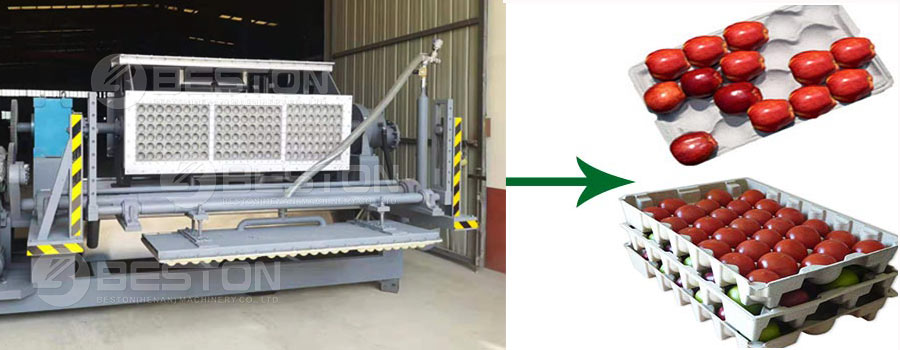

These machines are relatively small, and are sometimes maneuverable, allowing you to position them in your facility at the exact location you need. They can be shipped quickly, delivered to your place of business, and can be fully operational hours after they arrive. They use pulp which has been converted into a liquid form, typically made of some type of recycle biodegradable material. This will then be used in the trays to create the egg trays that you need for the products that you are producing. In this case, it is for protecting and shipping the eggs that you are producing. More information on egg tray making machine in Zambia here.

Would You Ever Need A Larger One?

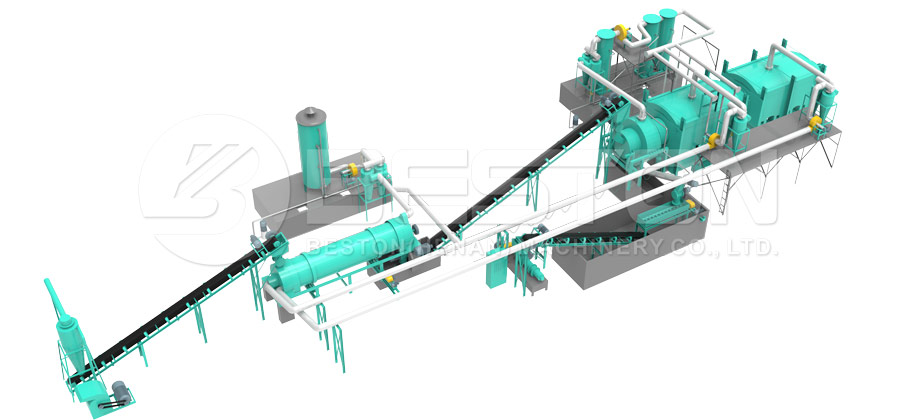

If your business is not growing exponentially, you may only be using the smaller model many months or years. If you do need to upgrade, you can always purchase an additional unit that can be connected to your conveyor belt system. In fact, the smaller units typically do not have a conveyor belt system. It relies upon individuals to collect the trays, stack them, and subsequently use them for the eggs that your farm is producing. On the other hand, if you are purchasing additional forms, you may want to invest in something larger that has a higher capacity to produce these trays.

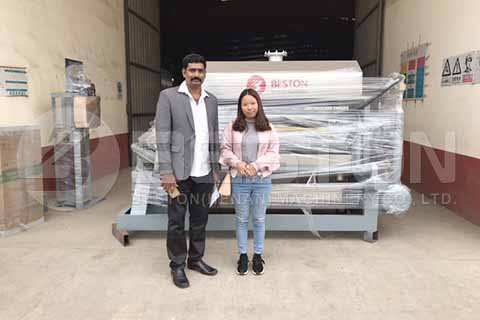

Saving money on these units is easy to accomplish if you are doing your research properly. For instance, instead of looking only in your immediate area, you may want to consider businesses outside of your community. Going overseas could be a good decision to make, primarily because they can produce these at a much lower price point. The savings will be passed on to the businesses that purchase the egg carton forming machine that produce these smaller quantities.

6pcs Egg Carton

To obtain a small egg tray machine, all you need to do is start looking for advertisements for them. You can go to their websites, evaluate the different ones they are currently offering, and make your decision promptly. By comparing different prices from a wide variety of businesses that specialize in industrial machines, you will find many that you will want to purchase. Consider their output, size, and their overall price, before making your final decision. The simple tips for relocating a smaller egg tray machine will help you save money and get access to one of the best ones sold today. Get how to make egg tray here.