Carbonization machine for sale can be used to process several biomass products. They simply make use of tech that was designed to treat waste effectively so that they can be disposed of. Materials like chips of wood, husks from rice, shells, from coconut and palms, wood, plant stalks, sewage sludge, and various others can finally be effectively processed in an efficient manner. The process employed within the carbonizer machines makes use of high temperatures, carbon enrichment, and sulfur emission.

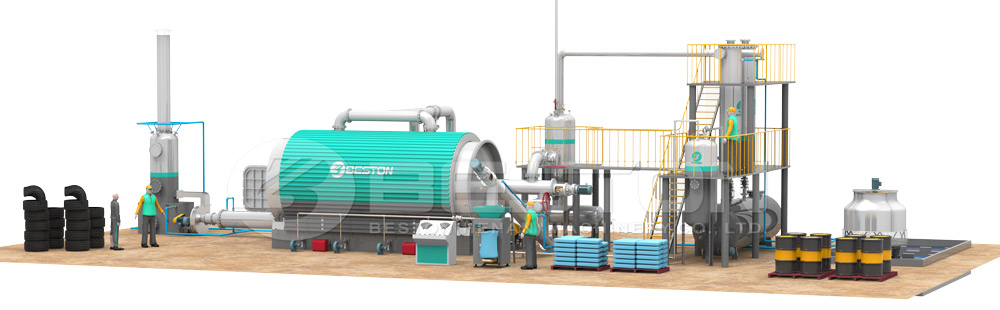

Qualified Carbonization Machine for Sale Manufactured by Beston

Carbonization machines easily produce charcoal and other products without air. In essence, it can be thought of as thermal decomposition being incomplete. As we’ve mentioned before, coconut shells, sawdust, bamboo, and various other materials can be used in this machine. Additionally, industrial sludge, civil sludge, and municipal sludge are also used. Accordingly, it can be called coconut shell charcoal machine, bamboo charcoal machine, etc.

These machines have the capability to be used in several different fields across the globe. They are effective in the agriculture and forestry field since the processing of wood, vines, coconut shells and many others are successful. They are also used for the treatment of industrial waste, and paper waste.

Carbonization machines can also be used to improve soil conditions. Leading charcoal making machine suppliers suit the delicate needs of customers. This enables the separation of machines and the operations that can occur. During this process, any combustible gas produced is simply recycled as it is returned to the burner.

Shipment of Carbonization Machine for Sale – Beston Group

The combustion device featured on the plant contains a pressure gauge and pressure relief valves. There is also an electronic ignition device. The machines casing has also been designed to be completely reliable hence persons will never risk coming in contact with extreme temperatures. The control system is also standardized to ensure safer operations.

The cooling system is state-of-the-art while operations are completely smoke-free. The general carbonizer design employs a multi-passage double layer. This system features auxiliary equipment, the drier and the carbonizing machine. Additionally, other important machine parts include the feedstock, discharging, driving, flash steaming, rack, cooling, wet dust catcher, exhaust gas recycling, and the gasification furnace. Here you can see how does the full set of machine work: https://bestonasia.com/charcoal-making-machine/.

As we’ve mentioned before, these machines can be fully customized to suit the needs of a customer. The double-layer mentioned before makes the bottom part of the machine maintain contact with the hot air. This is done in an effort to raise the heat. Hence, the application of heat is effective from the beginning of the process.

In an effort to further increase the use of produced heat, a combination of the recycling pipe, the flash steaming collection pipe, the carbonizing and fission heat collecting pipe, were all used for the third time where heat was utilized.

As we conclude, we have just looked at Beston carbonization machine for sale. These machines are effective in the way that they function and they effectively reuse certain produced elements during processing. They are a great way to reduce the waste produced by several industries.