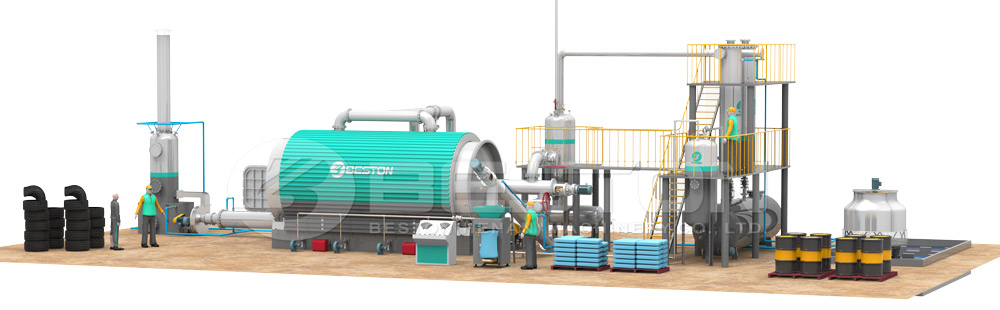

There’s an increasing number of plants that are utilizing recycles materials to make products with high value and the pyrolysis plant is one such good example. But is it really worth investing in one? If you are looking to get into the recycling business and are on the fence, here are some reasons to consider buying a tyre pyrolysis plant(planta pirolisis de llantas):

It is Easy to Get Rubber Waste

One of the primary benefits of getting a tyre pyrolysis plant(Planta Pirólisis) is that you won’t have to toil to get the materials you need to run it. In fact, if you are already in a business that produces rubber waste, it can be an effective way to recycle it.

Also, tyres are not the only source of recycled rubber. There’s a myriad of other ways for you to get hold of the rubber you require to run a pyrolysis plant. With numerous options, your plant will be able to run on a daily basis.

Oil is in High Demand

Pyrolysis machines produce oil; something that is almost always in high demand. While those who run these plants use the oil for their operations, you can sell it for a profit.

Regardless of the route you take, you will quickly realize that oil is highly valuable, and given it is not a renewable resource, its demand, particularly the oil from pyrolysis plants is bound to rise over time.

Many Options to Pick From

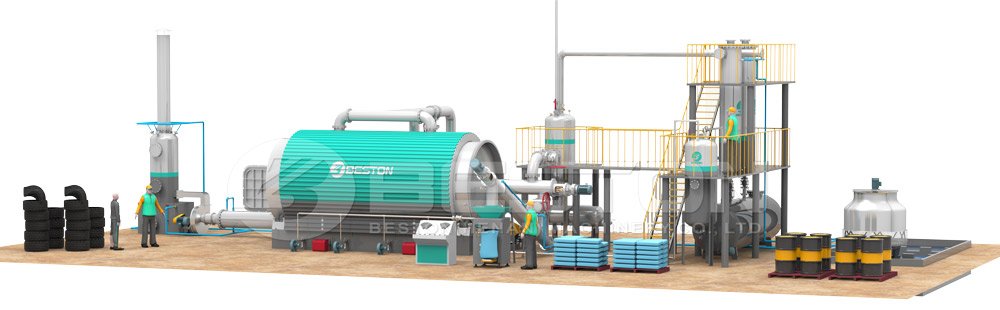

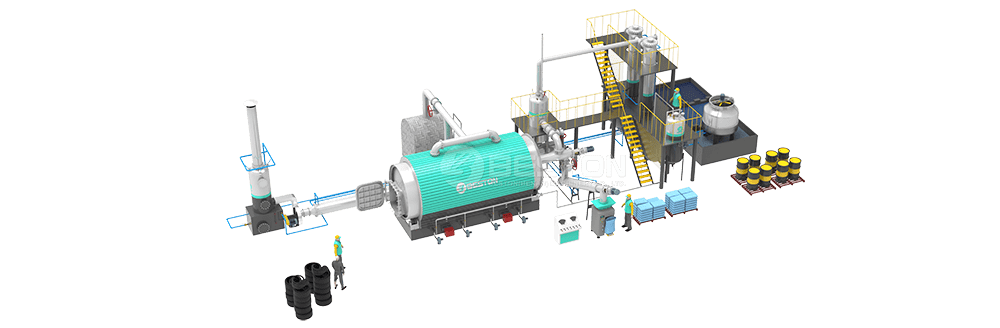

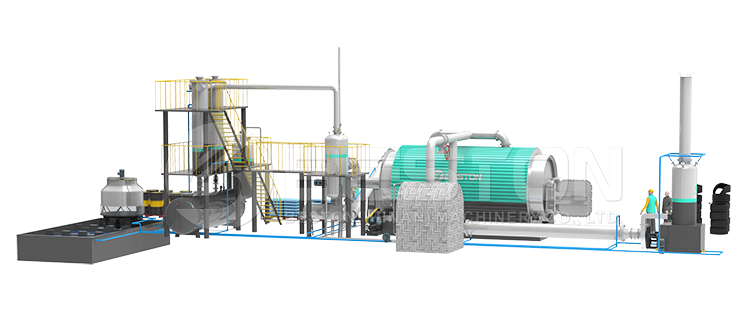

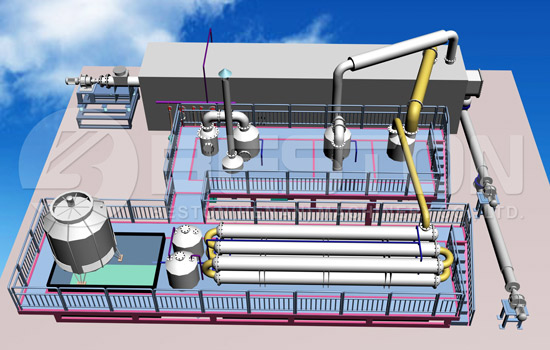

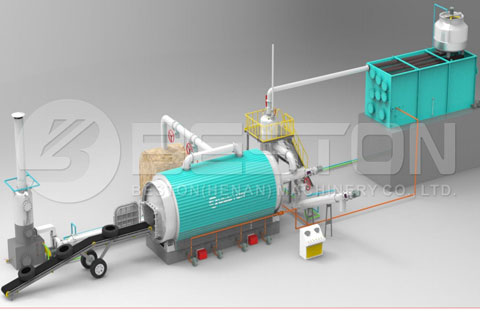

When you get the equipment you need for your tyre pyrolysis plant(https://www.bestoneco.com/planta-de-pirolisis/), you will have no shortage of options. You may decide to invest in the fully continuous type, but the options do not end there. With such a wide array of options, you will not have to make any compromises when picking the right equipment for your needs. You will be able to focus on finding a plant that’s well within your budget and do exactly what you need it to do.

Environmentally Friendly

In a day and age where everyone is trying to reduce pollution, investing in a tyre pyrolysis plant(Beston China) can reduce your carbon footprint. Given you will be working with recycled materials, the pyrolysis plant is bound to have a positive impact not just on your surroundings, but the environment at large.

These types of advantages are beyond personal. Depending on your region, you might be eligible for tax breaks when you invest in environmentally friendly machinery that uses recycled materials. In turn, tax breaks will make your operations more profitable, another reason to invest in a tyre pyrolysis plant.

As you can see, there are numerous benefits to purchasing a tyre pyrolysis plant. If you are on the fence about whether such a plant would be a smart investment for your company or surroundings, the above-mentioned benefits are things you will want to take into consideration. Ensure you weigh the pros and cons as they will help you make an informed decision. Also, it’s worth taking a look at trends in this niche and seek advice from experts to ensure you don’t end up wasting money.