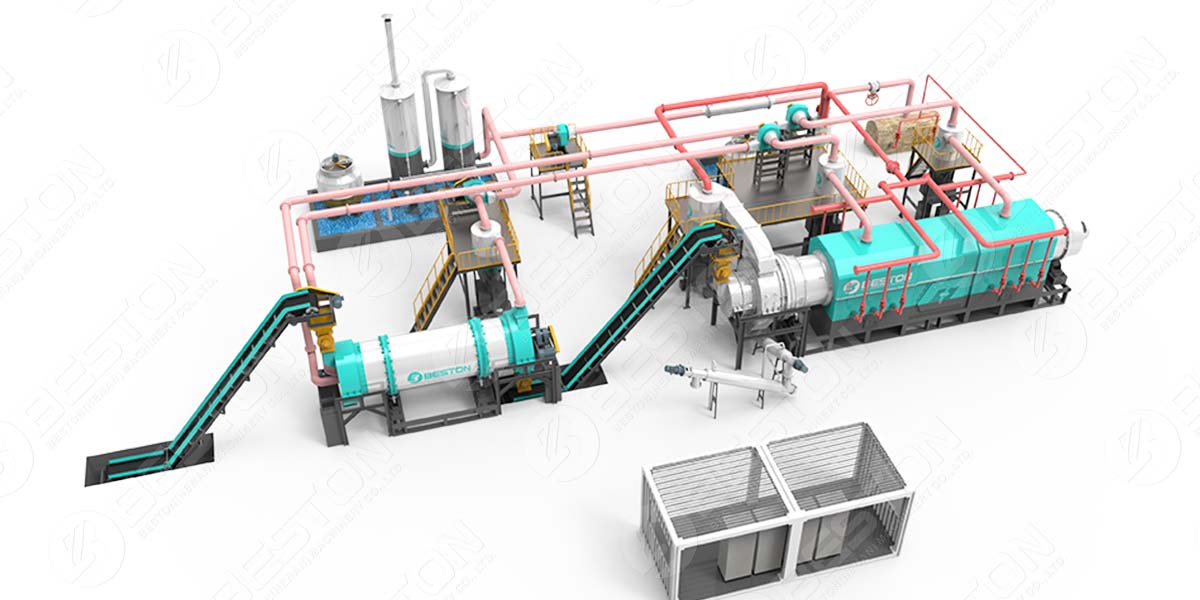

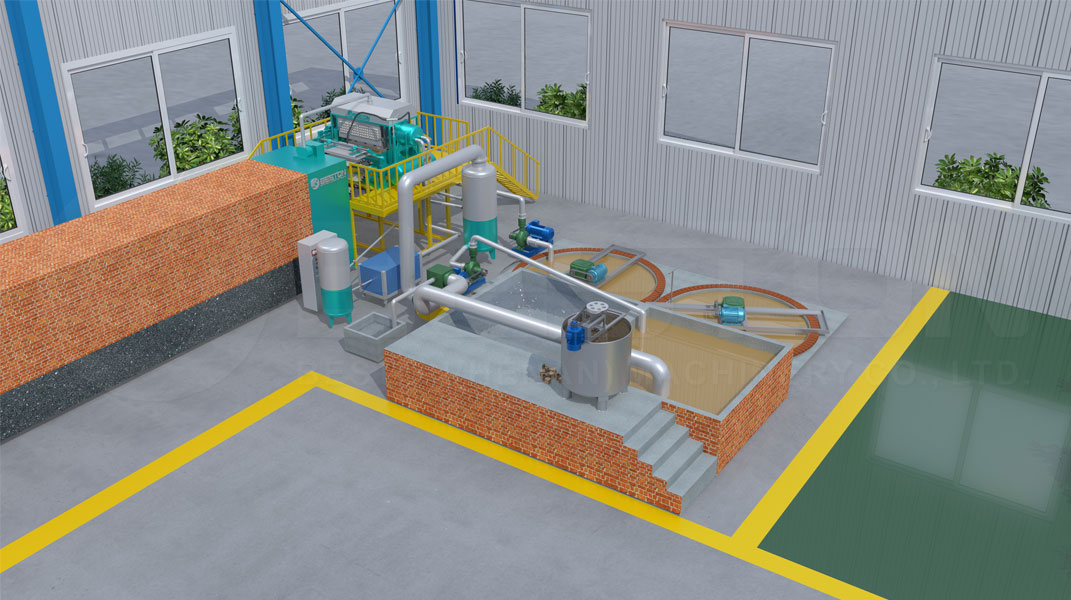

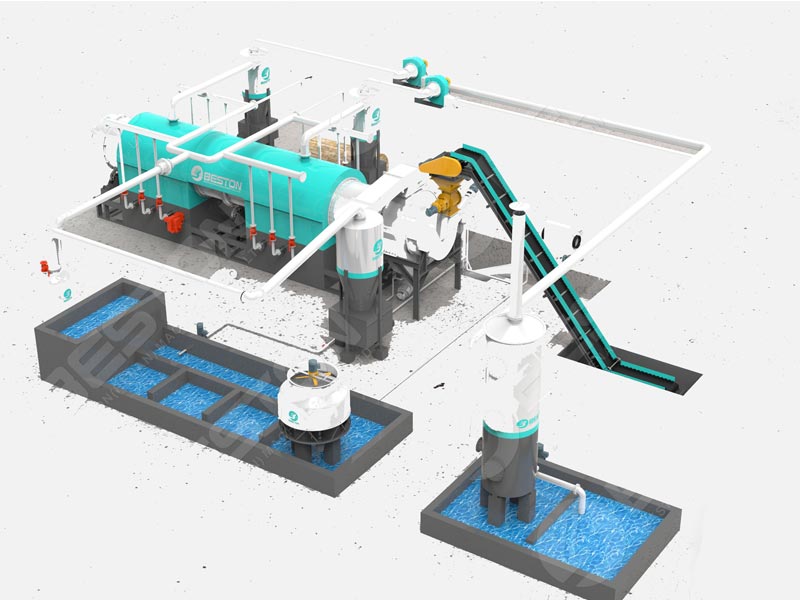

Biomass briquettes can be made of many materials. This will include plastic, rubber, sludge, rice husks, and even sawdust that is produced. The process by which this is broken down into a material that can be burned is made possible because of the pyrolysis plant or machine. This process is able to heat these materials, convert them into charcoal, as well as biofuel and bio oil. If you do have access to a large amount of biomass, you may want to consider this as a solid business option. To find manufacturers that do produce biomass briquette machines, here is how you can find the best companies(China Maquinaria de Beston Group).

Planta de carbonización

How Is Biomass Converted Into Burnable Briquettes?

Biomass can easily be converted through the pyrolysis process. Many people start with a small machine(maquina para hacer carbon) just to see how well it will work. However, for those that are at a municipal solid waste plant, where tons of material is coming in daily, they may want to upgrade to a full pyrolysis plant instead. To know what is available, you must first find the Manufacturers of these products. Regardless of where you are currently operating your business, you can always order one online.

How To Assess The Businesses You Find Online

Your assessment of these businesses should begin with determining how many they have produced. This can be estimated based upon how long they have been in business. You may also receive recommendations from people that you know that have also obtain one. In fact, there are businesses that use multiple pyrolysis machines and plants just to keep up with the biomass that they receive. To assess these businesses, you should also contact them directly. Speaking with representatives can be very helpful. They will eventually send you an estimate as to the total cost of one of these machines. This will enable you to start converting these waste products into biomass(planta de carbonización) briquettes.

Is There A Market For Biomass Briquettes?

There are certain areas of the world where burning biomass for heat, and for cooking, is just as common as turning your lights on. They do not have another option when it comes to producing heat for their home. Therefore, they will be more than happy to utilize these products. From the perspective of someone that is producing the biomass briquettes, you may want to first consider finding vendors that already have clientele. By simply providing them with the briquettes that you are able to produce, you will have a constant way of generating revenue from your efforts.

Biomass(https://www.bestoneco.com/maquina-de-carbonizacion-montado-sobre-patines/) briquettes have been used for centuries, by people all over the world, for cooking and heating their homes. If you would like to enter this industry, you must first have a consistent supply of biomass that you can use. It will also justify the purchase of a biomass briquette machine that you can purchase as your own. After learning how to use it, it will be one of the easiest ways to generate extra revenue for your company and at the same time eliminate biomass in a profitable manner.