Interested in buying a tire recycling plant? Do you want to set up a successful business recycling waste tires? If the answer to these questions is yes, you have come to the right place. In this article, we are going to discuss how you should go about buying a pyrolysis oil machine for sale in order to set up a successful tire recycling business.

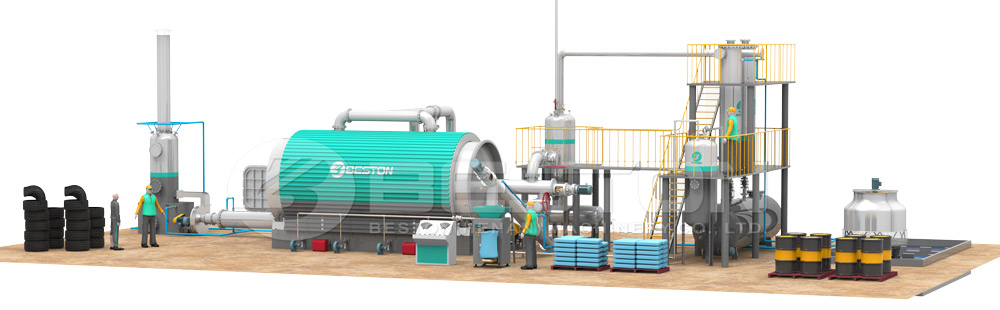

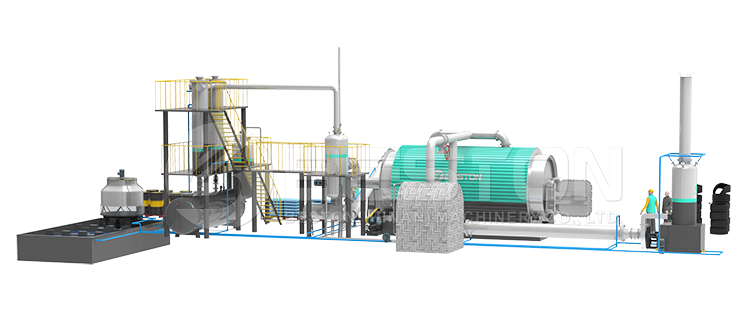

Tire Recycling Plant in Turkey

Waste tires are a huge problem around the world. Millions of tires are sent to landfills each year and these waste tires create a lot of problems. Thankfully, there is technology available today that allows anyone to set up a business recycling these waste tires. The good news is that tyre pyrolysis machinery is a profitable business provided you take your time to research the technology required for setting up and operating this business.

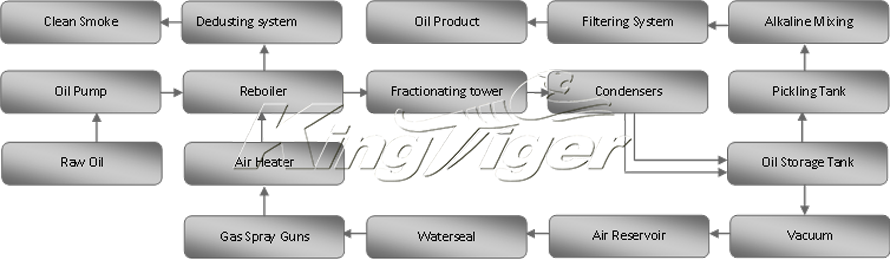

This technology is known as the pyrolysis process. In this process, large molecule chains are broken down into smaller molecule chains under immense heat and pressure. The materials used for making modern tires are made up of large chain molecules. When these molecules are broken down, these convert to something known as tire oil and other useful products. The tire oil can then be further distilled to get diesel and other oils that are in huge demand across a variety of industries. In short, waste tires can be recycled profitably.

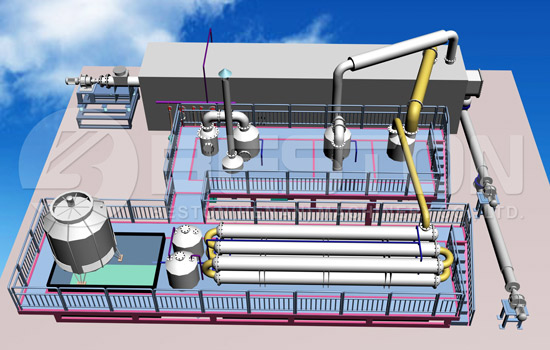

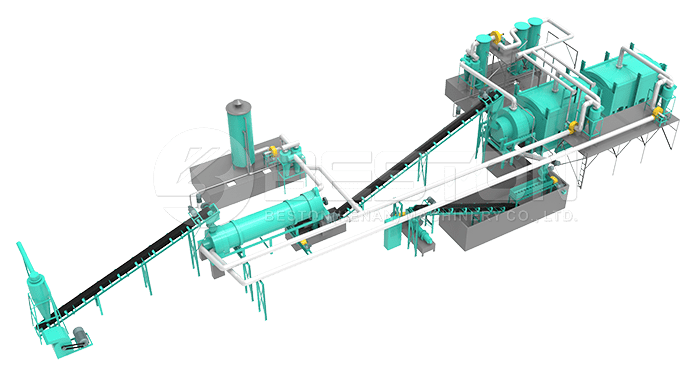

Pyrolysis Plant Design

Thousands of tire recycling plants have been set up all across the globe but not all of those plants are profitable. The biggest difference between a profitable plant and a loss-making plant is the technology in use. Plants that have been set up decades ago use technology that is highly inefficient. The modern technology available today is much more efficient. Modern technology makes sure that you get a much higher output. Also, the pollution regulations are much more stringent today as compared to a few decades ago. The modern designs also make sure that your pyrolysis plant is in compliance with the latest pollution regulations. More details here: https://bestonasia.com/waste-tyre-oil-plant/.

When you go out there to research different types of tire recycling machine for sale, there are two important things you need to carefully consider. One of the things you need to look at is the capacity of the plant. Higher capacity means you’ll be able to produce tire oil in huge quantities at a much lower cost. However, higher capacity plants cost a significant sum of money. Therefore, you need to begin by preparing a business plan before you start looking at tire recycling plants available for sale.

If you do not have any experience in this business, it is better to tie up with someone who is knowledgeable and knows about the latest happenings in this industry. It could be someone you know or a vendor willing to help their customers set up a successful business. There are quite a few vendors who help their customers set up a tire recycling business. They will help you prepare a business plan and make sure your business complies with the local pollution regulations.

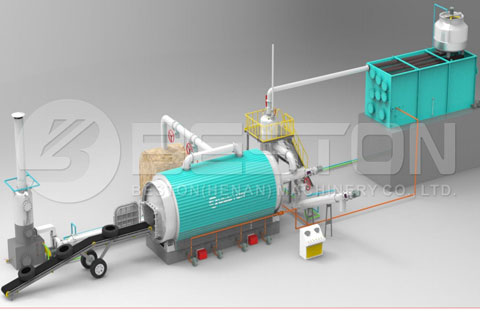

Overall, a tire recycling business with Beston Machinery Co Ltd can be very successful provided you do your research before investing money in various components including the tire recycling plant. It is recommended to partner with someone (could be a vendor) who is knowledgeable and will help set up a strong foundation for a successful business.